Automatic Deburring Machine – Intelligent Robotic Solutions for Loading and Unloading

In industrial sheet metal processing, automatic deburring plays a crucial role in removing burrs and sharp edges from workpieces after laser cutting or punching. Especially with larger parts and/or high production volumes, manual loading and unloading quickly reach their limits—or become increasingly costly. This is where automated systems such as robotic deburring come into play: they provide a precise, reliable, and economical solution for post-processing sheet metal components.

Our Deburring Solutions

Whether individual components or ready-to-use application systems – we offer flexible solutions for automated deburring, tailored to your specific requirements.

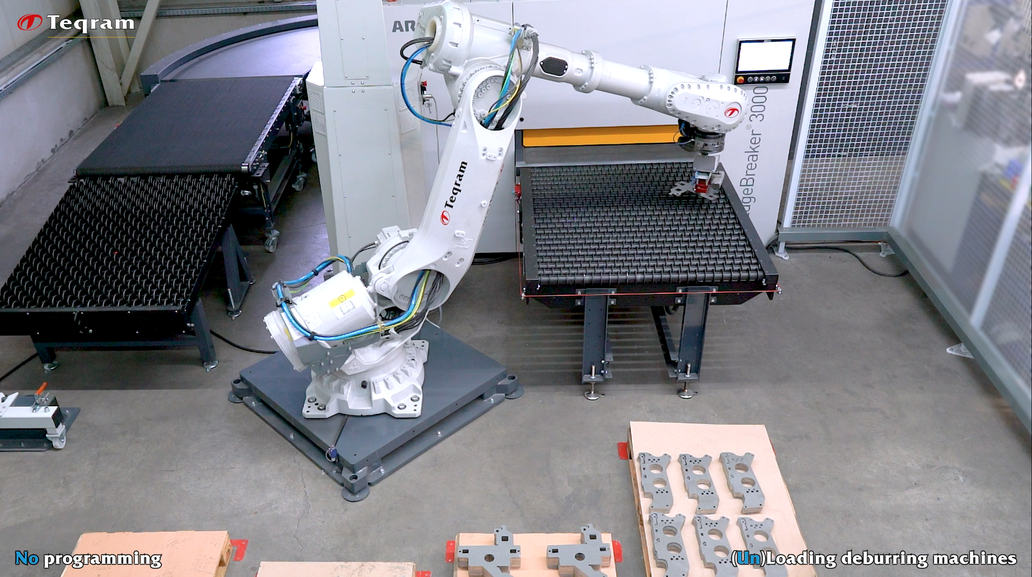

Teqram combines selected deburring machines from renowned external manufacturers with perfectly matched handling robots (EasyBots) and vision-guided camera systems (EasyEye) enhanced by AI. This enables stable, efficient, and fully customized deburring processes that meet your exact needs.

No Programming. No Teaching.

The Three Key Elements of Fully Automated Deburring

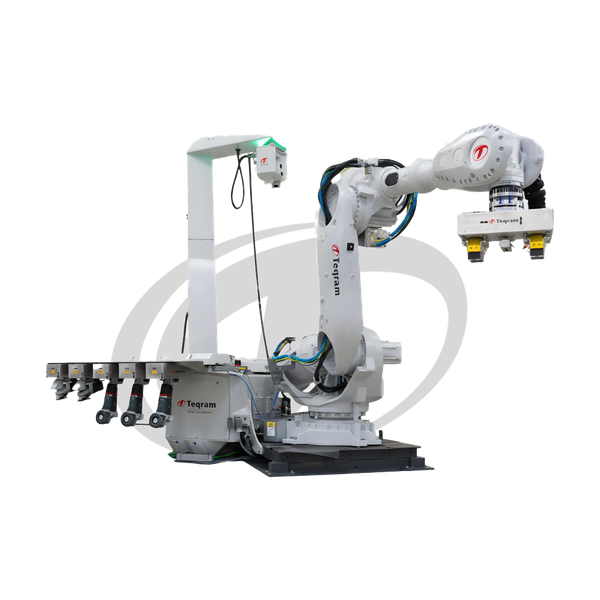

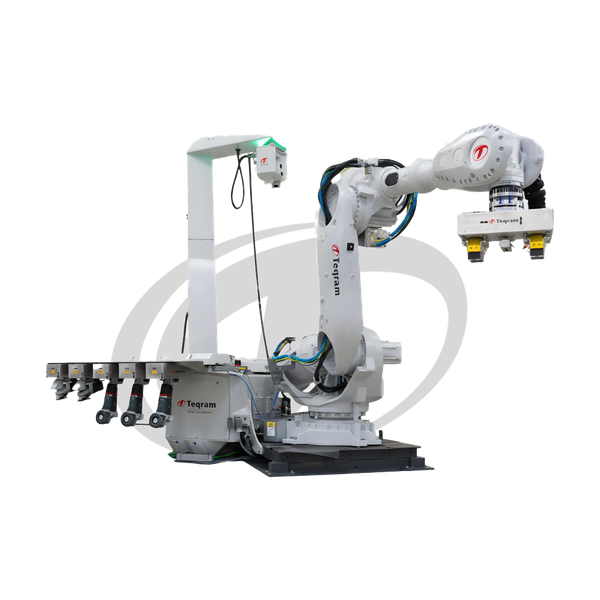

Easy Bot (Teqram)

Teqram robot arms equipped with the appropriate end effectors.

EasyEye (Teqram)

Camera system for vision-guided automation.

Deburring Machines

Deburring machines from external manufacturers (e.g., ARKU EdgeBreaker 4000).

In combination, they create customized robot-and-machine configurations for fully automated deburring →

Request your custom automated deburring solution today!

EasyDebur in Three Variants – The Right Solution for Every Workpiece

Our deburring solutions combine proven deburring machines with intelligent robotics for handling and machine loading—completely without programming. EasyDebur is our modular robotic solution for automated deburring, available in three payload classes designed for workpiece weights of up to 130 kg [287 lbs], 200 kg [440 lbs], or 600 kg [1,323 lbs].

Easy Debur 130

Up to 130 kg [287 lbs] – ideal for almost all laser-cut or punched parts.

Easy Debur 200

200 kg [440 lbs] – suitable for very large sheets as well as flame-cut and plasma-cut parts.

Easy Debur 600

600 kg [1,323 lbs] – designed for extra-heavy and oversized components.

All variants are based on the same modular platform. They are equipped with a vision system, automatic gripper selection, and intelligent tool changing—without programming or teaching. Even large sheets up to 2,400 mm in length (and beyond) can be handled by our systems.

Teqram deburring robots – fully automated and completely free of manual programming!

Integrate EasyDebur into your processes today

boost your productivity with Teqram’s automated deburring robot.

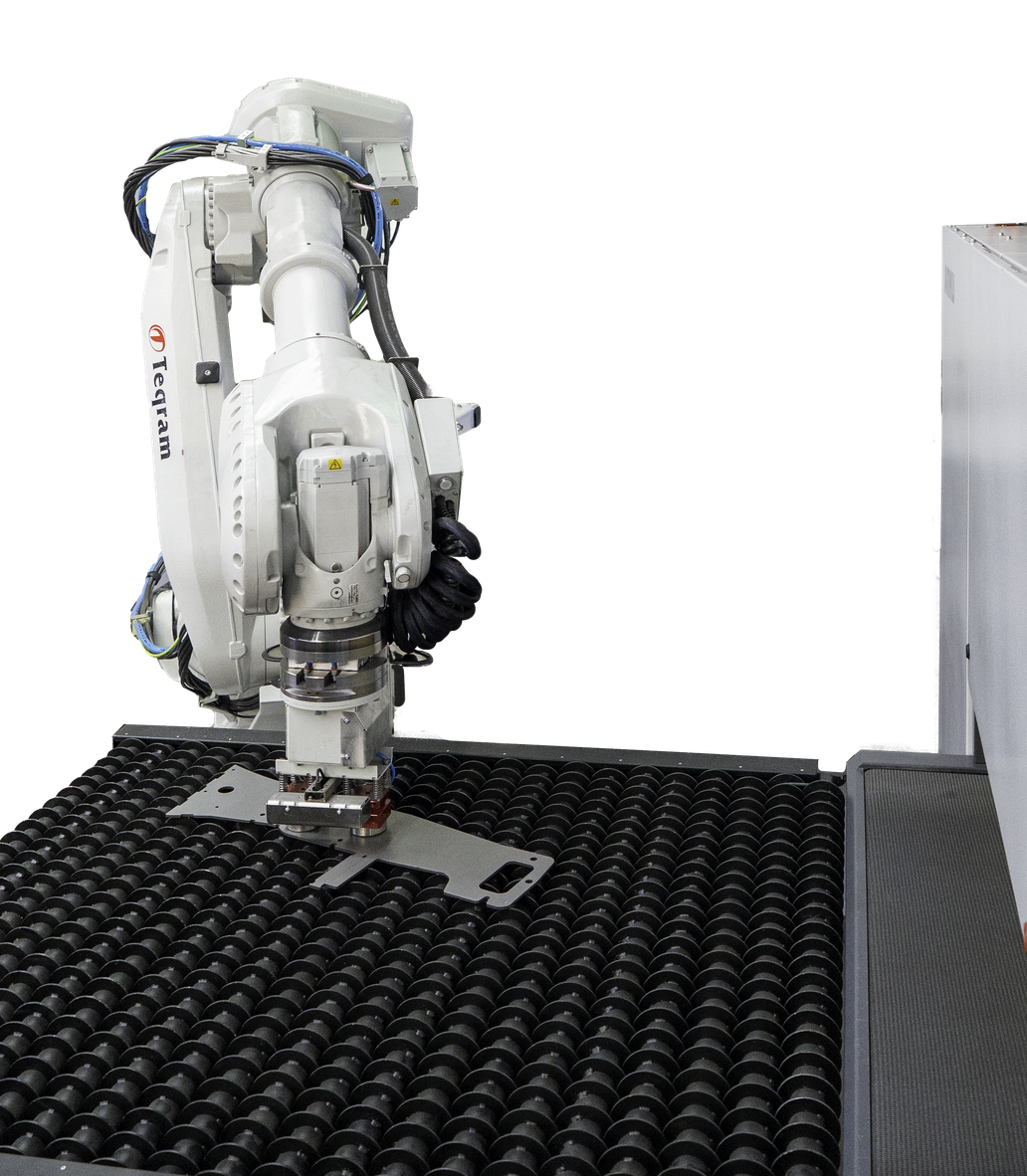

How the Robot Works

- Workpiece Detection and Loading – Using our AI-supported vision technology, the system identifies the workpiece geometry and automatically positions the part on the roller conveyor or feed belt for loading into the deburring machine.

- Unloading / Flipping for Second-Side Processing – After processing, the robot removes the workpiece. If required, it flips the part for second-side processing and feeds it back into the deburring machine.

- Automation of Single-Sided Deburring Machines – Even single-sided deburring machines can be automated without manually flipping the workpieces—the robot performs this step for you.

Your Benefits with EasyDebur – Everything from a Single Source, No Programming Required

With EasyDebur, you receive a fully automated solution for deburring sheet metal parts—without programming effort, without special fixtures, and with maximum flexibility in operation. The intelligent combination of robotics, vision technology, and adaptive self-adjusting grippers makes EasyDebur the ideal solution for efficient, safe, and economical deburring processes.

- No programming required – EasyDebur automatically identifies parts, selects the correct gripper, performs tool changes, and starts the process—without teaching or manual programming.

- High flexibility in handling – Simply place your cut parts on pallets; no special fixtures or exact alignment are needed. Even single-sided deburring machines are supported—the robot flips the parts using the EasyFlipper.

- Intelligent self-programming included – Our AI-powered vision technology reliably detects geometries and automatically switches grippers, ideal for constantly changing part types.

- Greater safety with heavy parts – Especially for heavy components, EasyDebur reduces manual handling—lowering the risk of injuries and significantly easing the workload for your staff.

- Faster than manual processing – Automated loading and unloading, combined with the elimination of manual steps, significantly reduces cycle times.

- Easy operation for everyone – The intuitive user interface makes EasyDebur easy to operate—no robotics expertise or special knowledge needed.

Bring EasyDebur into your processes now

Boost efficiency with Teqram’s automated deburring robot.

Seamless Integration into Your Processes

EasyDebur automates your deburring machine. The robot cell detects, grips, loads, and unloads—without any manual intervention. Both simple and complex workflows can be fully implemented (single-sided, double-sided, or multiple feed cycles).

Technical Foundation – The Technology Behind EasyDebur

EasyDebur is a modular solution for the automated loading and unloading of deburring and grinding machines. The system architecture is based on Teqram’s flexible robotic modules and can be precisely adapted to customer-specific applications—whether for stand-alone machines or fully integrated production lines.

The Heart of EasyDebur: The EasyBot

Every EasyDebur cell incorporates our specially developed EasyBot—a vision-guided robotic module that handles all core tasks. An EasyBot consists of:

- EasyEye – our patented 3D vision controller for workpiece-based detection and positioning

- 6-axis industrial robot – with a reach of 3.05 m [10 ft] or more, suitable for sheet metal parts ranging from just a few hundred grams up to 600 kg [1,323 lbs]

- Modular base – compact, easy to transport, with integrated safety and control technology

- EasyIO – decentralized I/O system for reliable control

- EasyFlexibleFramework – a software platform for flexible, vision-guided workflows

- PC-based user interface – intuitive to operate, no additional PLC required

- Gripper change system – with electrical, pneumatic and data interfaces

Thanks to its consistently modular design, EasyDebur can be seamlessly integrated into existing systems.

Suitable for Single- and Double-Sided Processing

If double-sided deburring is required, the system is supplemented with the EasyFlipper—an automated flipping station that rotates the workpiece and transfers it back for a second processing cycle.

High Product Variety? No Problem.

Thanks to vision technology and self-configuring software, EasyDebur is perfectly suited for small batch sizes and frequently changing part geometries — with no programming required.

Other Robotic Solutions

Below you will find further automation solutions from Teqram that may also be relevant for your operations:

With EasyGrinder, you achieve consistently precise grinding results—powerful, uniform, and reliable. Ideal for series production and demanding parts, EasyGrinder ensures perfect surface finishing and consistent material removal, all without manual effort.

EasyMillDrill automates your machining processes. Workpieces weighing up to 600 kg [1,323 lbs] are placed into the machining centers and the program is started automatically. This includes flipping the parts, optional re-feeding, and external blowing-off of chips and coolant. This enables unmanned shifts and ensures perfect machine utilization.

Teqram’s robotic solutions bring automation to a new level—flexible, reliable, and individually adaptable. Whether handling, assembly, or specialized processing, here you can explore our entire range of robotic solutions.

Automated Deburring at Teqram – Request Your Non-Binding Consultation

At Teqram B.V., intelligent automation and customized robotic solutions are at the core of what we do. With many years of expertise in metal processing, we develop innovative systems that make your production processes more efficient, flexible, and future-proof.

Our smart robotic solutions are tailored precisely to your requirements. From the initial idea to final commissioning, we support you as a reliable partner—with one clear goal: taking your manufacturing performance to the next level.