EasyMillDrill

Automated (un)loading of Milling machines

Loading and unloading of milling machines can be labor-intensive. For heavy parts, which need to be handled by crane, manual loading is slow and tedious work for the operator.

Automated loading and unloading of milling machines

Loading and unloading heavy workpieces on CNC milling machines can be a time-consuming and labour-intensive task. Automating this was previously very difficult, especially when dealing with small quantities and high variety.

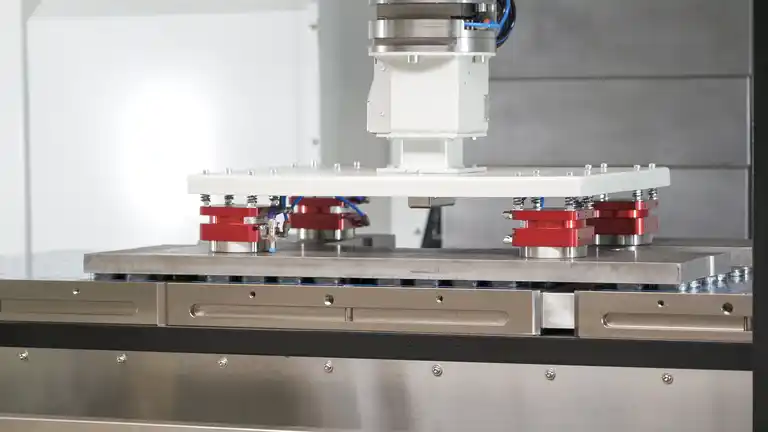

Teqram's technology, the use of vision-guided robotics and easy-to-use software solves this problem. The EasyMillDrill is a robot equipped with vision technology that is perfectly suited for loading and unloading products with a high variety and low volume in combination with a milling machine / machining centre.

No programming required

Thanks to our vision-controlled robot technology, the parts are recognised automatically. It is not necessary to teach individual workpieces. The software decides which gripper is the right one and changes it fully automatically.

Any operator can control our robot technology using the intuitive user interface without any special knowledge.

EasyMillDrill is also very easy to use with special clamping devices!

Typical Applications

- Loading & unloading milling machines or automated drilling machines

- Standard solution available for parts up to 600 kg

- Handling laser-, plasma- and oxy-fuel parts

- for parts out of steel, stainless steel, and aluminium

Parts can be automatically turned by the robot before and after the milling process! Fully automatic processing of both sides is therefore also possible.

Vision guided robots increases production efficiency significantly

Talk to us. We listen!