Automated (un)loading of Part Levelling Machines

Due to a range of different causes, metal parts frequently need to be straightened. The advantages of part levelling machines are becoming ever more evident. Teqram has automation solutions for the levelling machines of Arku - the global leader in levelling technology.

(Un)loading of levelling machines is labor-intensive and the risk of injury is always present. For heavy parts, which need to be handled by crane, manual loading is slow and tedious work for the operator.

Vision guided robots increases production efficiency on part-levellers significantly

Typical Applications

- Loading & unloading leveling machines

- Standard solution available for parts up to 200 kg

- A bigger version of the robot allows parts up to 600 kg

- Handling laser-, plasma- and oxy-fuel parts (steel, stainless steel, and aluminium)

Key Benefits

Vision Guided Robotics for loading and unloading levelling machines

‘Normal’ stacking and transportation of parts

Conventional robot systems need to know exactly where parts are located. EasyLevel uses Teqram’s vision-sensors & software, and is therefore significantly more flexible. Parts ‘offered’ to EasyLevel do not need to be stacked in special containers or jigs.

Speed and Safety

EasyLevel is significantly faster than a human operator in handling parts over 20kg each. Robotic handling of heavy parts eliminates the safety risks during manual handling by the operator.

Minimal programming required

Because of our vision-guided robot technology, parts are automatically detected and handled (in standard use cases). No teaching of individual parts necessary! Grippers are chosen automatically and gripper changes do not need to be programmed. A simple-to-use user interface ensures no ‘special’ knowledge required for operators.

Technical Specifications

EasyLevel is a solution for (un)loading levelling machines. It is built on Teqram’s modular building blocks and can be adapted to specific applications.

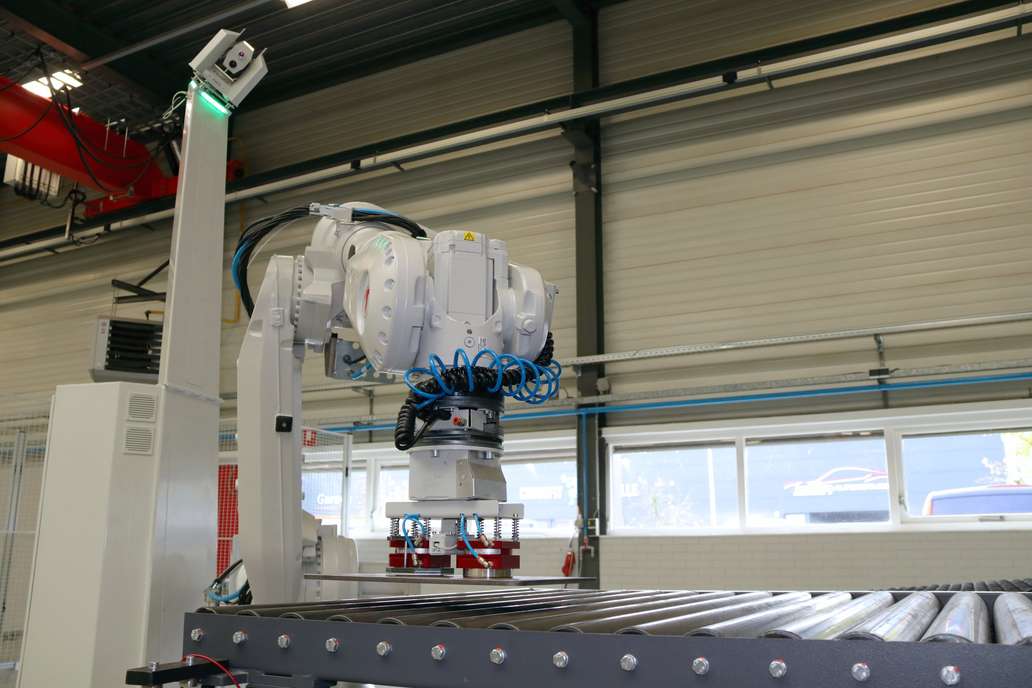

A central component of our solutions is our vision-guided robot as a module: the EasyBot.

The EasyBot contains:

- Our patented 3D vision controller (EasyEye)

- An industrial robot manipulator with 6 axes, 3.05 m reach and able to handle products up to 200 kg (optional 600 kg)

- Modular base (easy to transport and place) with all electronic & safety components EasyIO: distributed IO & control

- EasyFlexibleFramework: software framework for vision-guided robotics

- PC based User Interface: Easy to Use, no PLC needed.

- Gripper-change adaptor (robot-side) with data, electrical and pneumatic connections

- And much more…

Due to our vision technology, an EasyBot can deal with low-volume high variety production challenges. In comparison with conventional robot-solutions, an EasyBot facilitates an extreme reduction in programming times.

EasyLevel can seamlessly cooperate with an EasyFlipper to flip parts upside-down automatically when necessary for further processes.

Are you interested in significant more efficient (un)loading of your levelling machine ?

Talk to us. We listen.

Give us a call or email: