Deslagging and robotic grinding of oxyfuel & plasma cut parts by robot - without programming

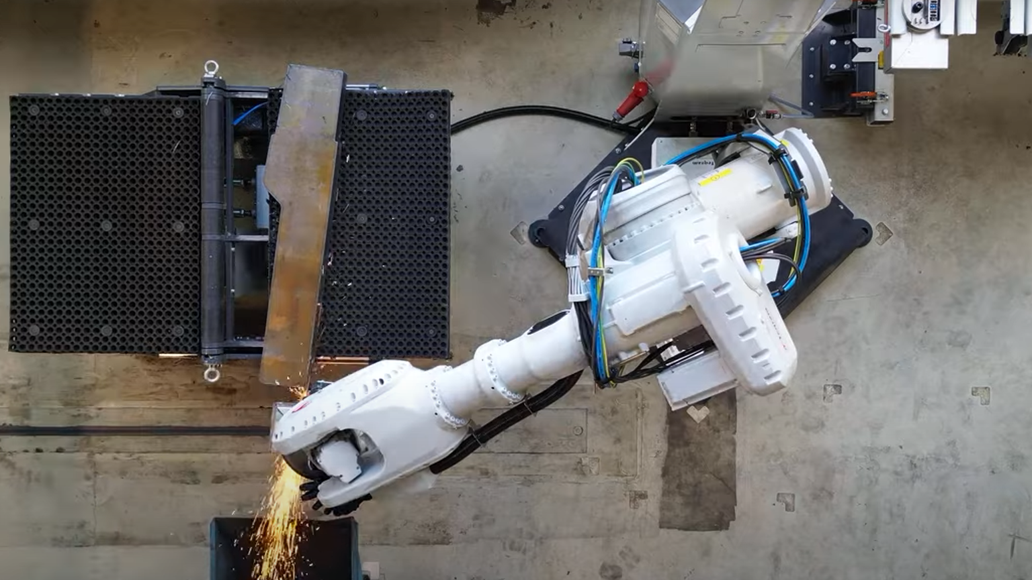

Cleaning flame-cut parts is a physically strenuous activity with a high potential for injury. The grinding robot EasyGrinder by Teqram does this for you without having to be programmed! Vision technology combined with AI makes the previously unimaginable possible! Robotic grinding at its best.

Customer-Example: EasyGrinder @ Ancofer Steel

Vision technology - no programming

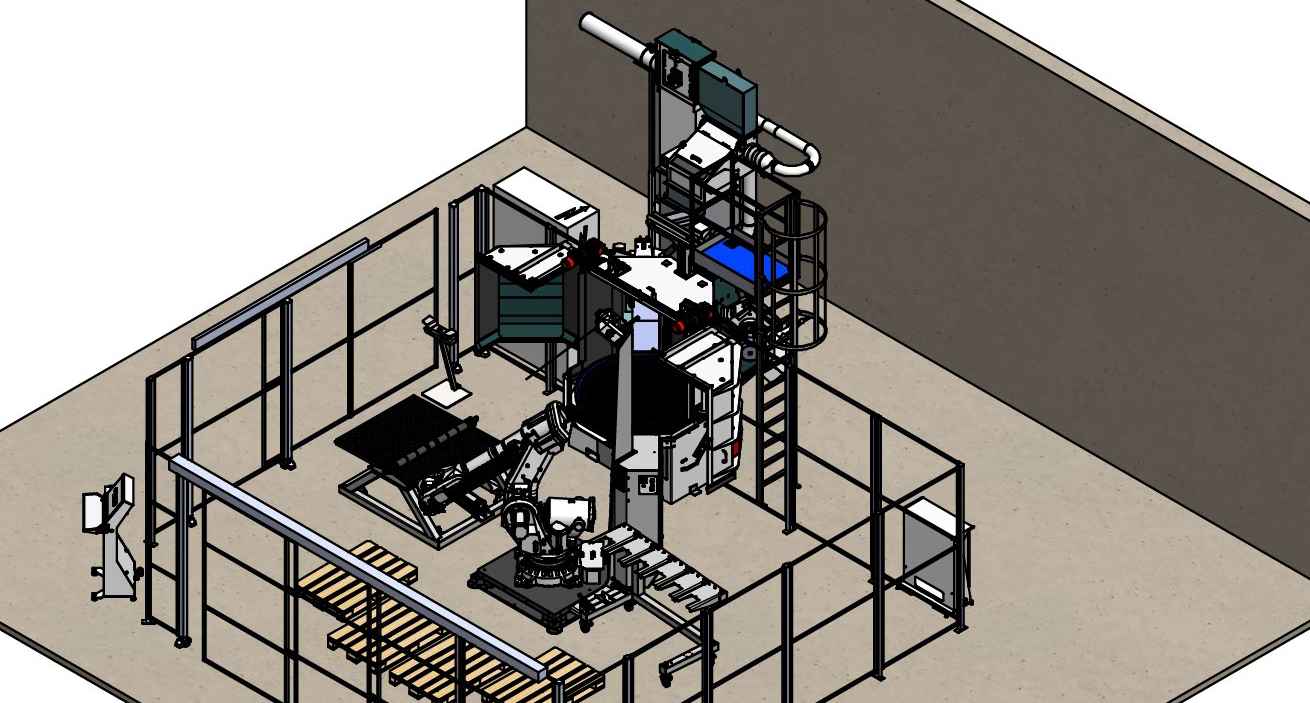

Thanks to our award winning vision technology and AI, no programming or teaching is required! By combining several imaging processes (time of flight, HD camera, 3D vision sensors), the grinding robot EasyGrinder recognises the geometry of the sheet metal parts autonomously and creates the programs for deslagging, edgerounding, ... for itself.

You want more information about robotic grinding?

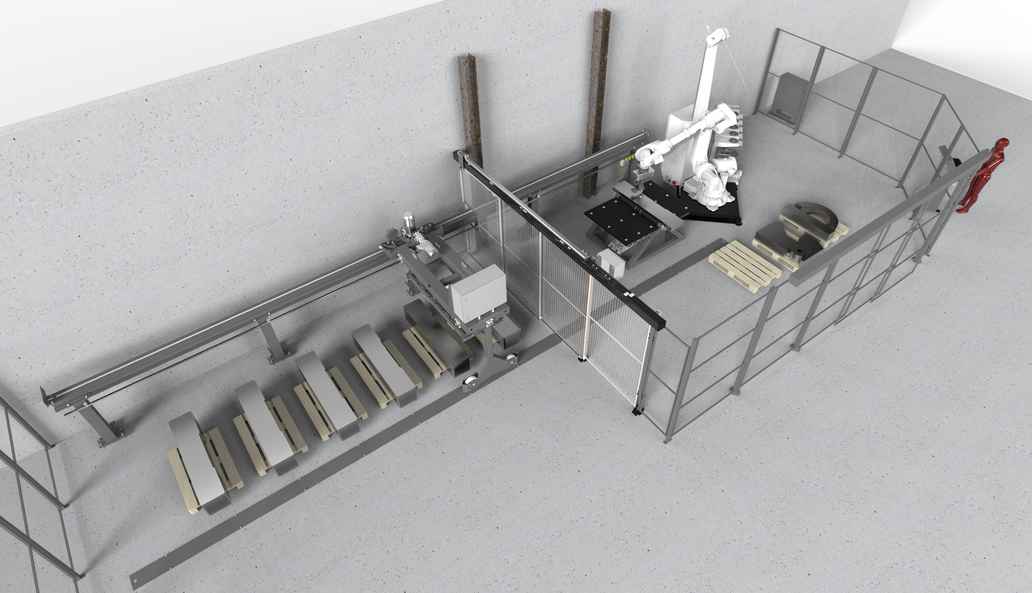

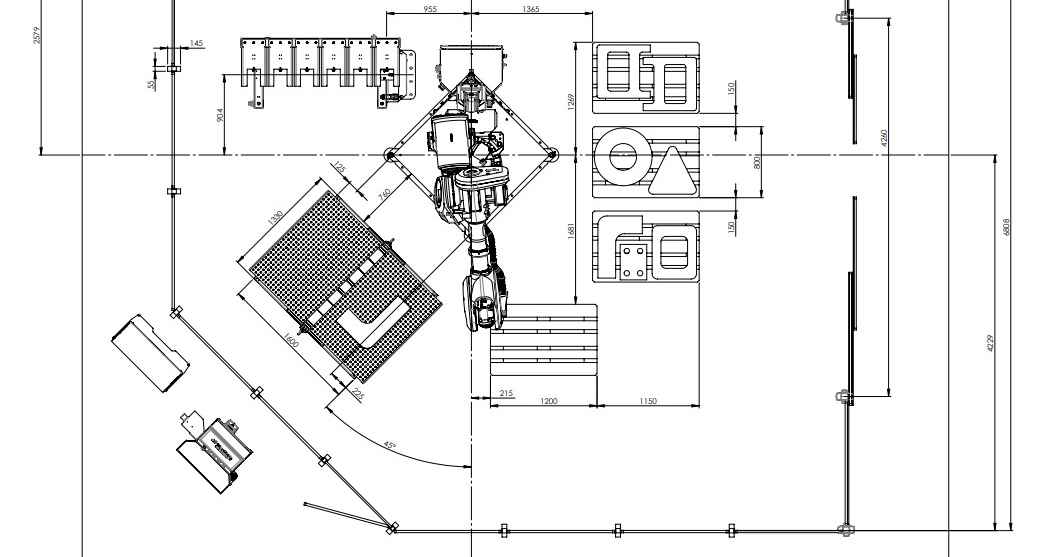

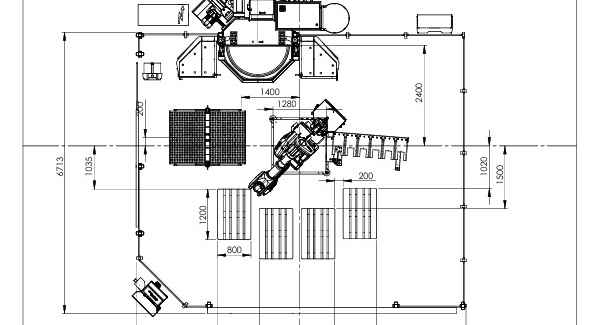

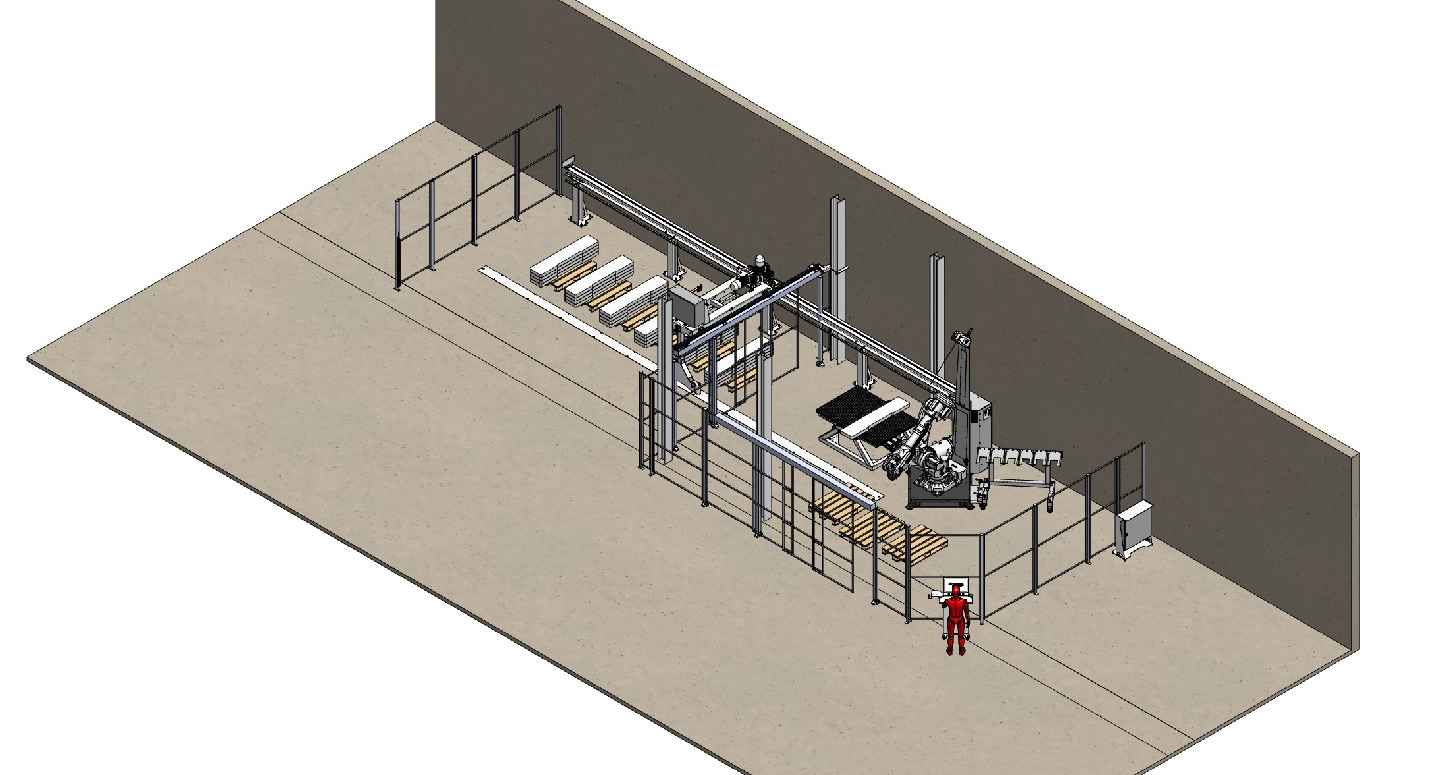

The standalone EasyGrinder can process oxyfuel- and plasma cut parts weighing up to 200 kg. They are provided on pallets and the grinding robot works autonomously once the desired processing quality has been selected.

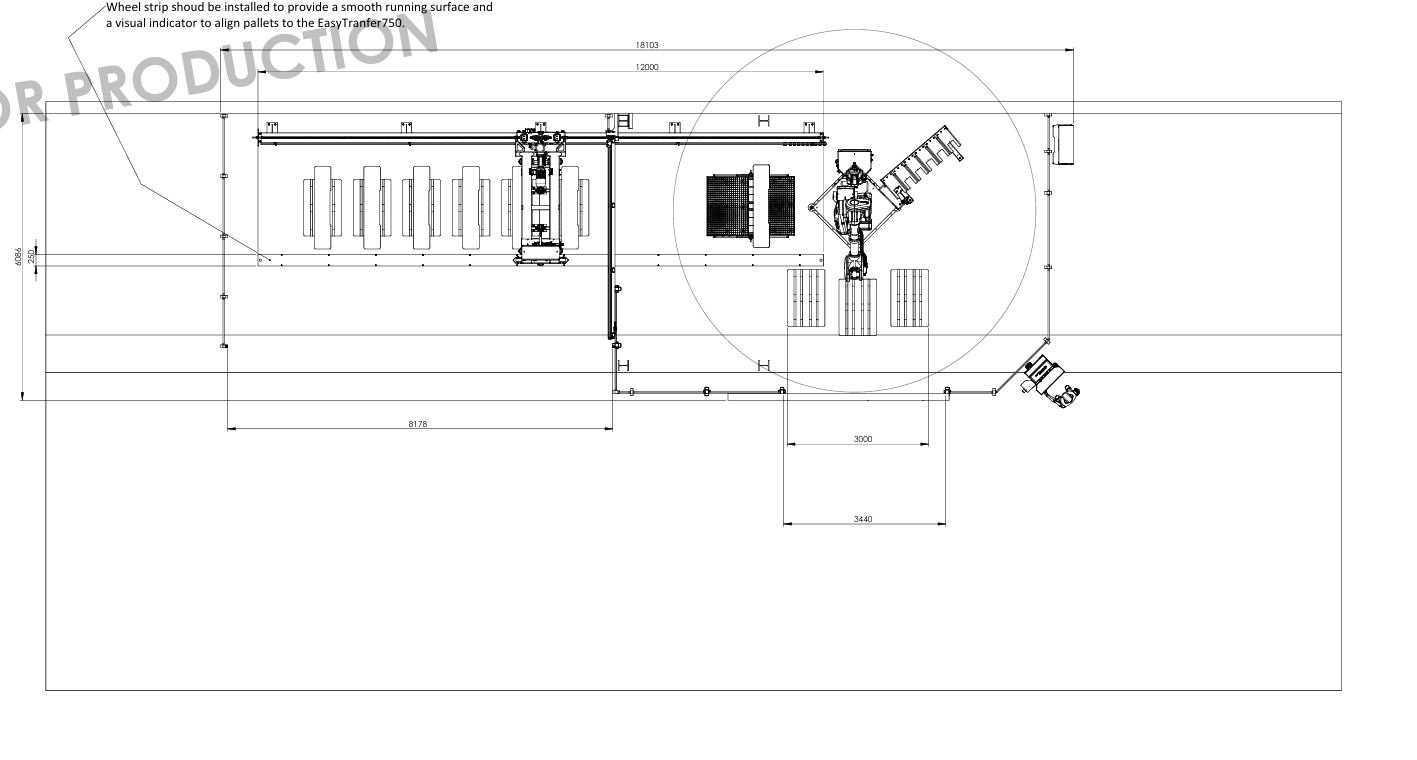

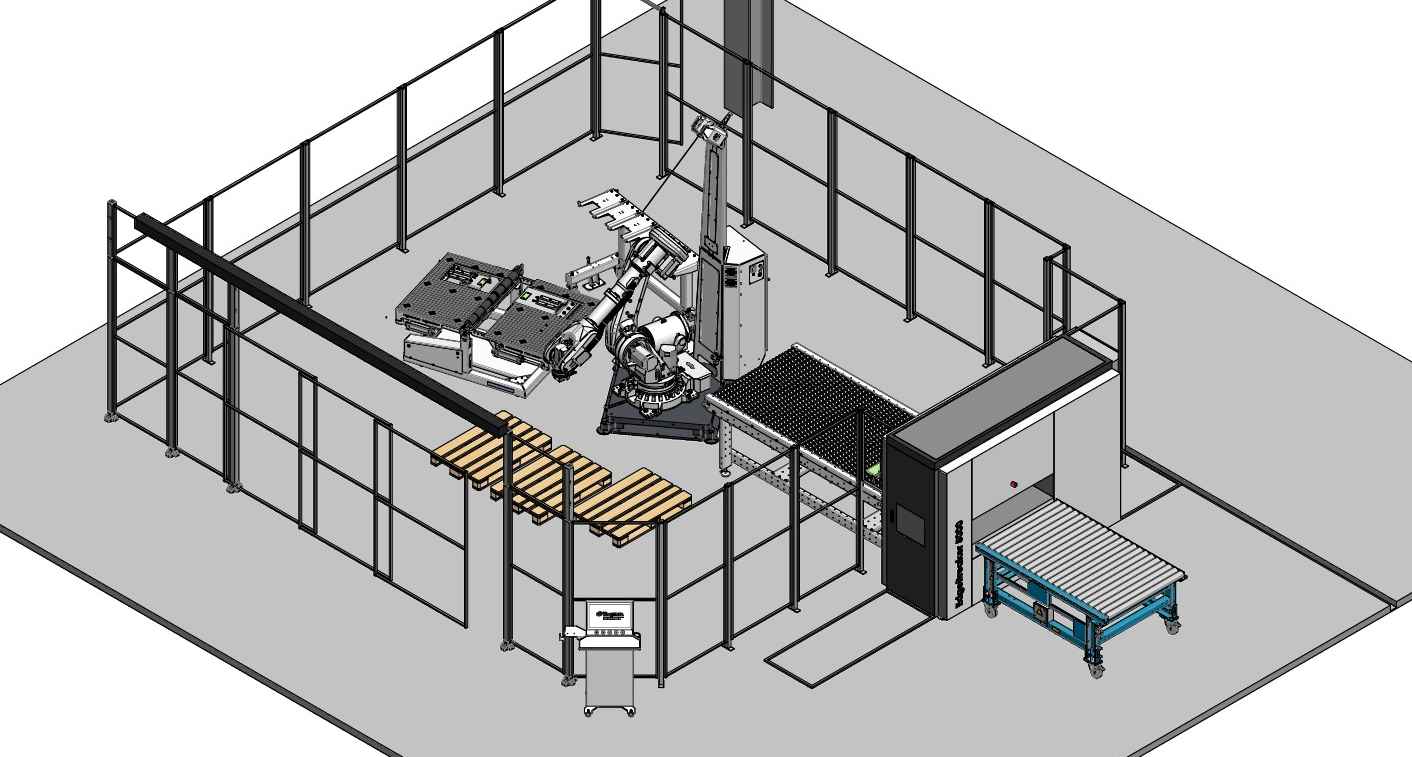

Customer-Example: EasyGrinder @ Klöckner Metals Germany in Bremen

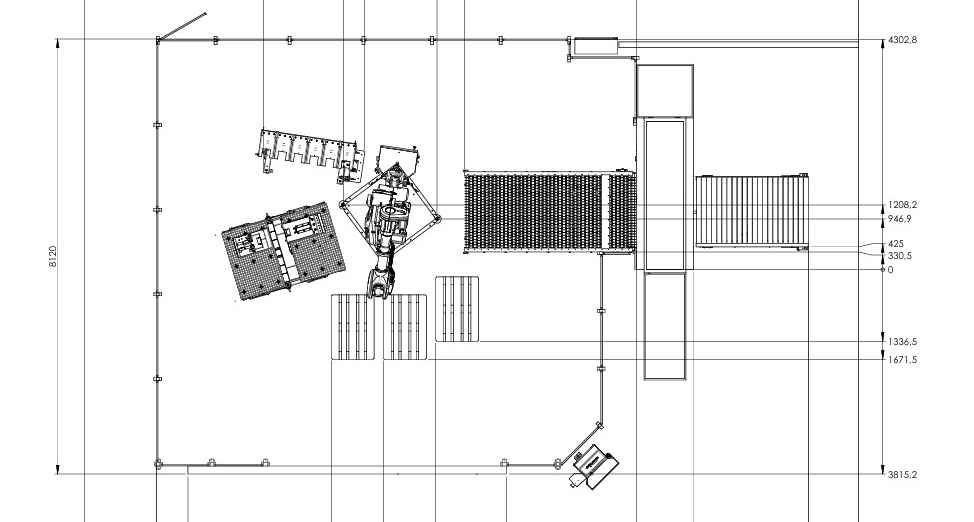

Flame-cut parts weighing up to 750 kg can be processed using the optional EasyTransfer system

Possible process steps:

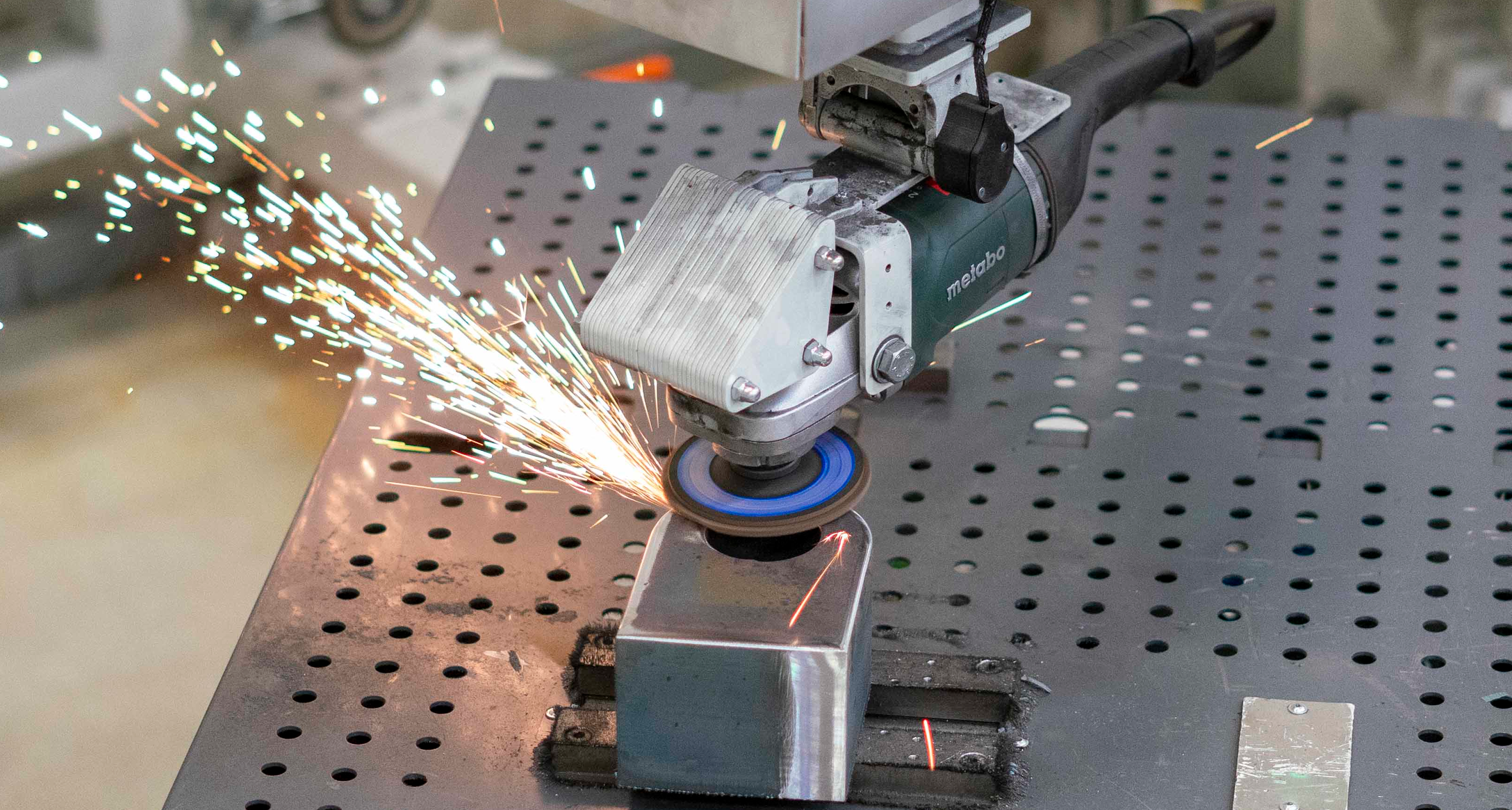

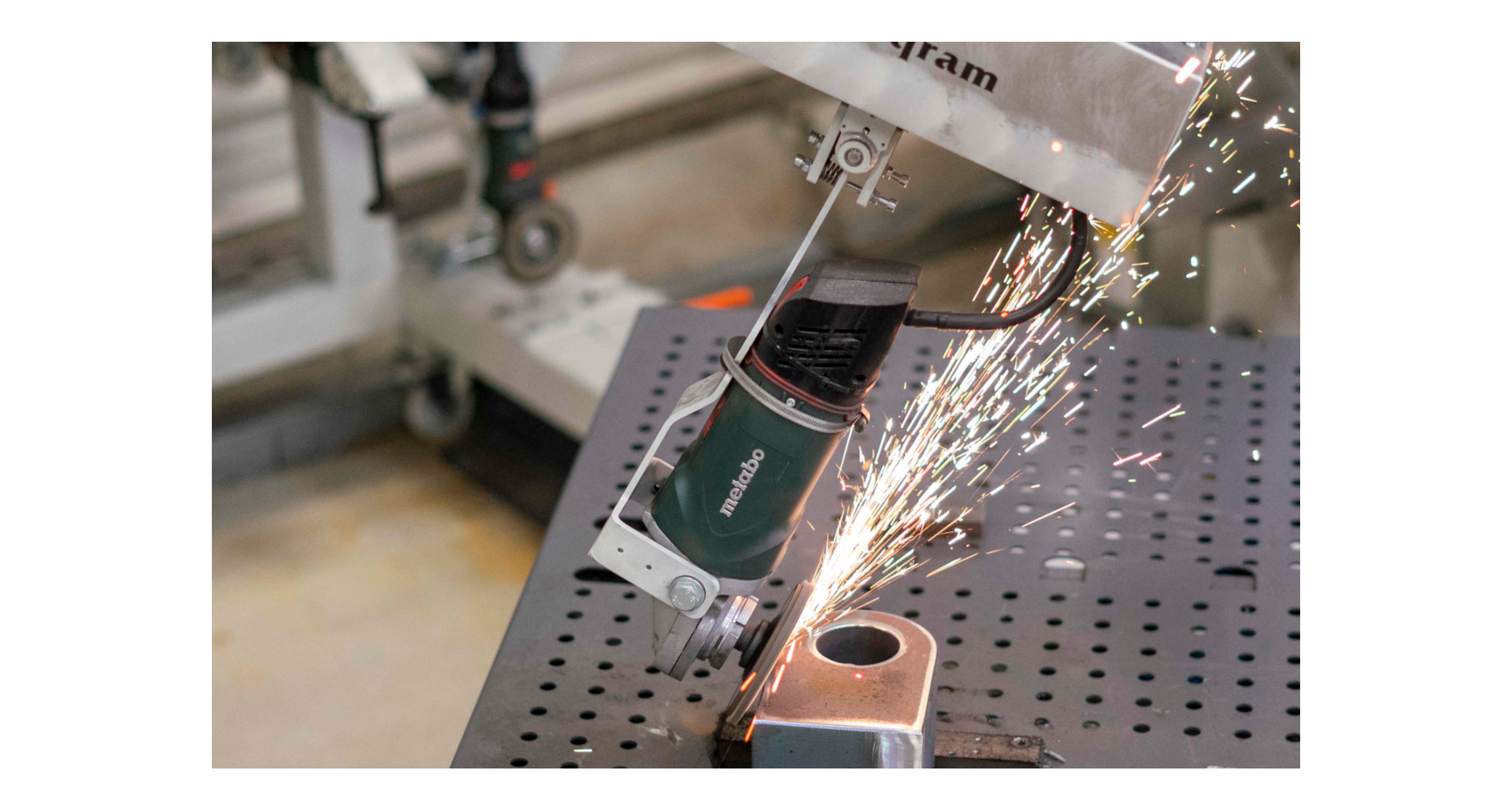

- Robotic Deslagging

- Edge breaking or Edge rounding by robot (up to R3)

- Grinding of the narrow edges (Hardening of the cutting edge)

- Removal of Start/Stop marks

- Robotic Deburring & edgebreaking of bore holes by robot

- Stamping & part identification

Examples of possible processes with robotic grinding:

Deslagging, edge breaking, edge rounding up to 3 mm, oxid removal, grinding the narrow edges (heat affected zone), removal of lead-ins

The desired processing quality is selected via stored recipes. For example, parts for one customer can only be chisseled, while other parts are given a radius of 2 or 3 mm!

Consistent quality

Manual deburring is not only monotonous but also physically very strenuous. Sooner or later, your strength wanes, quality suffers and the odd workpiece edge is forgotten.

Not so with robotic grinding. 100% consistent results and constant, predictable output - guaranteed thanks to the grinding robot EasyGrinder!

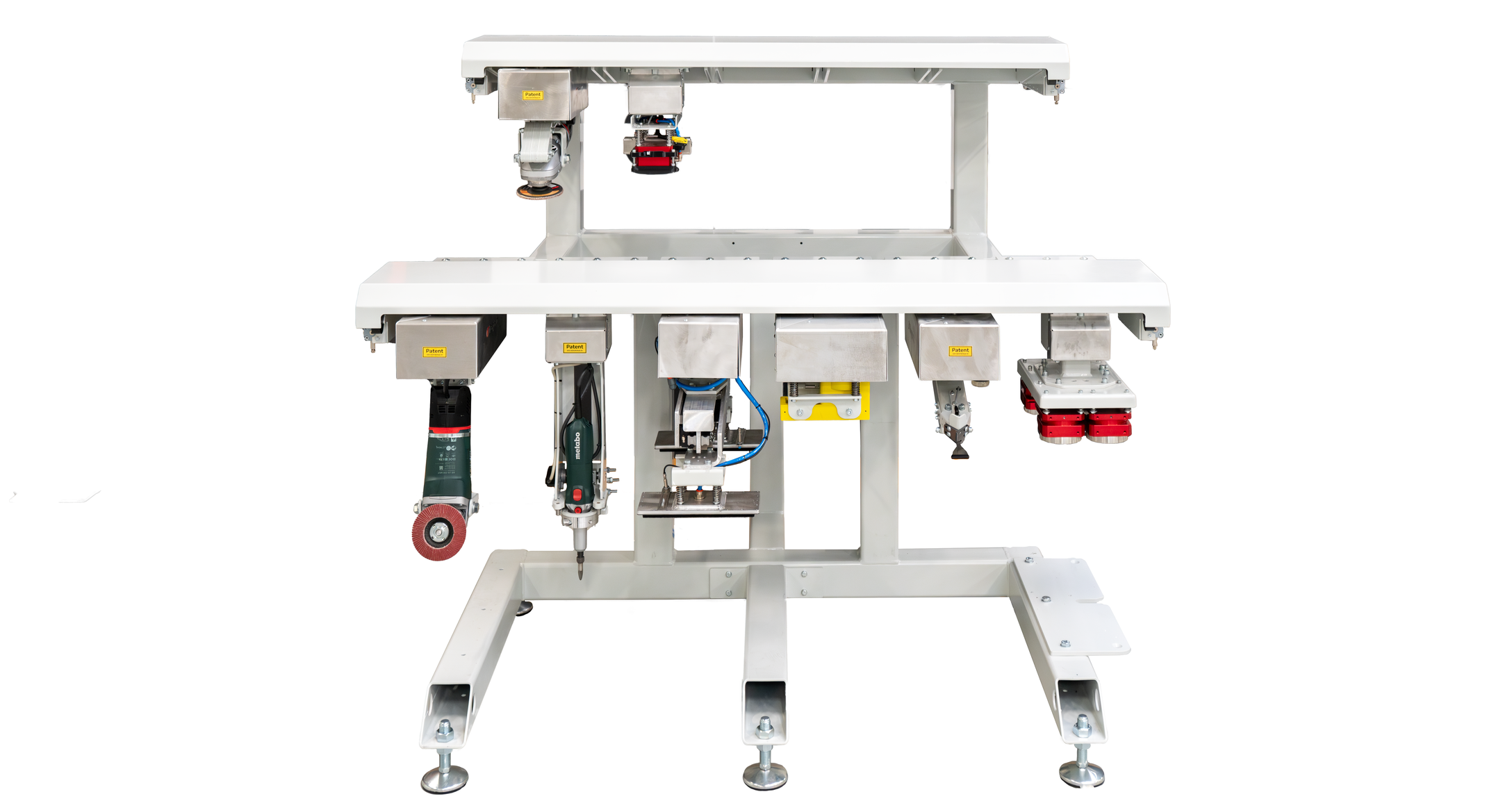

EasyGrinder Tools (click through):

Main advantages

with vision-controlled grinding robot

Increase in productivity

The grinding robot EasyGrinder identifies the sheet-metal parts and its contours using computer vision. The robot picks up the flame- or plasma-cut part, selects the right tool for the job and starts processing.

Extended possibilities

Deslagging, deburring, edge rounding and removal of oxide layers without programming. The robot's performance enables grinding processes that are impossible for humans.

100% consistent quality

Robotic grinding reduces your overall costs and also achieves higher and more consistent quality! Even the wear of the grinding tools is monitored automatically.

Different configurations of the grinding robot EasyGrinder (click through):

Technical specifications:

The grinding robot EasyGrinder is our solution for removing slag, deburring and rounding as well as removing oxide layers.

- The parts are supplied to the robot on Euro pallets

- Sheet metal parts with weights of up to 200 kg can be picked up and handled by the robot (for systems with high autonomy)

- Sheet metal components weighing up to 750 kg are fed to the robot via the EasyTransfer system

- The PC-based user interface is very easy to operate

- No special programming knowledge is required

- Necessary gripper & tool changes are performed automatically

- Various standard EasyGrippers are available, customised grippers can be manufactured on request.

- A wide range of standard and cost-effective grinding tools can be used.