EasyShotblast - robotic loading of shotblasting machines without programming

By automating this process, quality can be significantly increased at the same time as energy and labour costs are drastically reduced. The blasting of flame-cut parts is very labour-intensive. Systems that are designed for blasting sheets are often used for single sheet metal components. Flame-cut and/or plasma-cut parts are laboriously placed on grids using a lot of manpower.

EasyShotblast works completely unmanned and requires no programming!

EasyShotblast is a fully automated blasting solution for flame-cut and plasma parts without programming!

Your oxyfuel-cut and plasma-cut parts are recognized automatically. Completely unmanned and without programming!

Further informations on automized shot-blasting?

Call us! We listen!

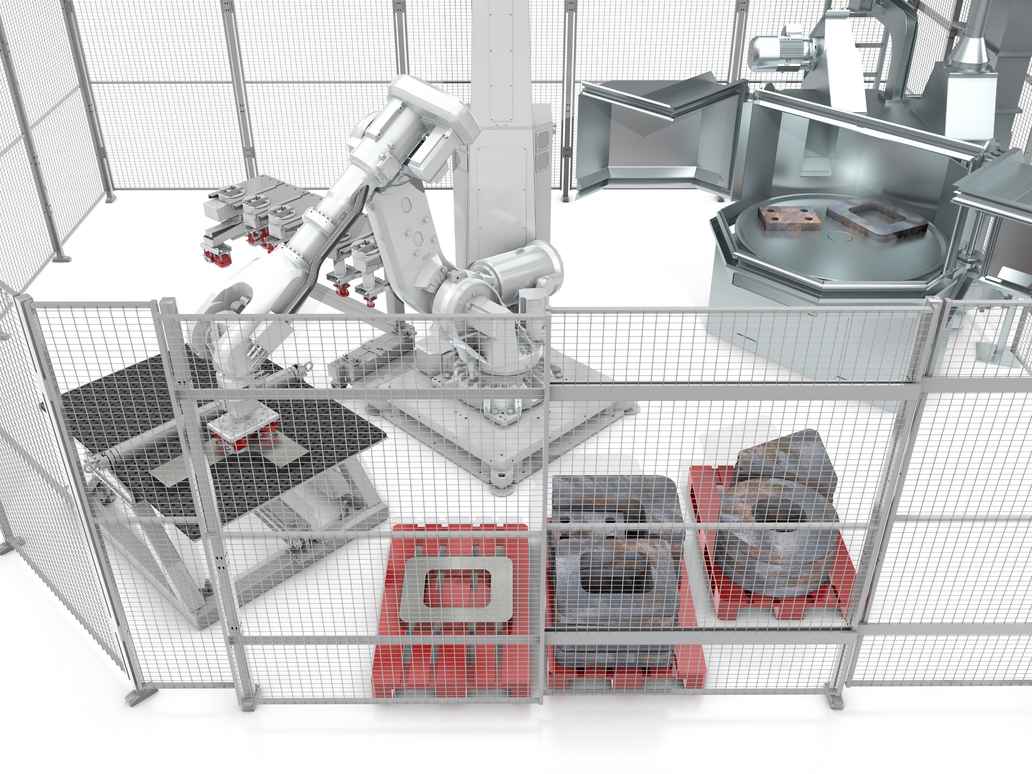

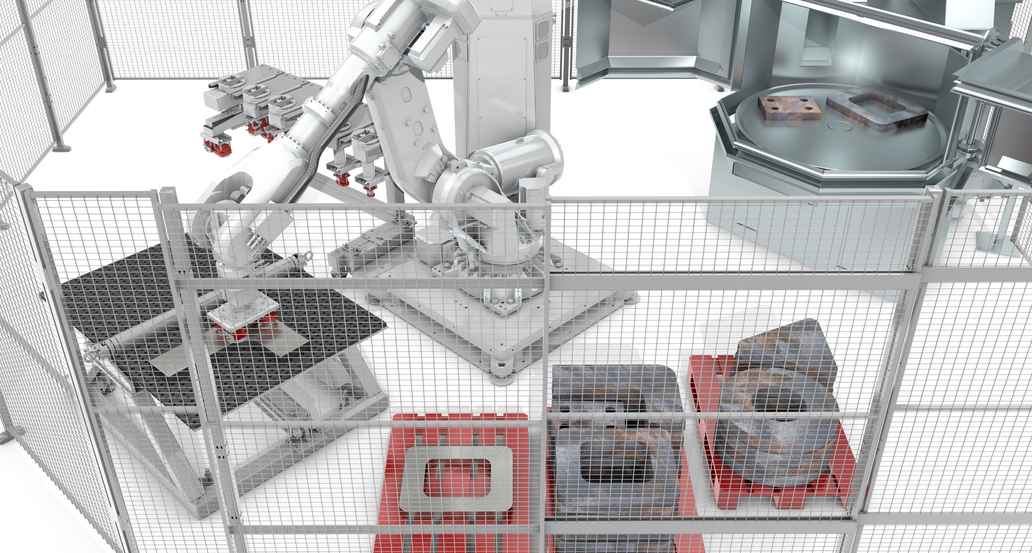

Simply place pallets with e.g. flame-cut parts in the robot cell. The EasyShotblast decides autonomously how many of your sheet metal parts will fit into the blasting system and blasts them on both sides.

With only 2 x 7.5 kW, surfaces with Sa 2.5 are reached within approx. 30-60 seconds per side!

Blasting systems with wire belts can also be loaded and unloaded completely unmanned. Combination with continuous deburring machines are also possible!

Main advantages

Vision-controlled robot for blasting systems

Fully autonomous without teaching / programming

Thanks to vision-controlled robots, the sheet metal parts are recognised and suitable grippers are selected autonomously.

The user interface is intuitive and requires no specialised knowledge.

The robot fits seamlessly into existing processes

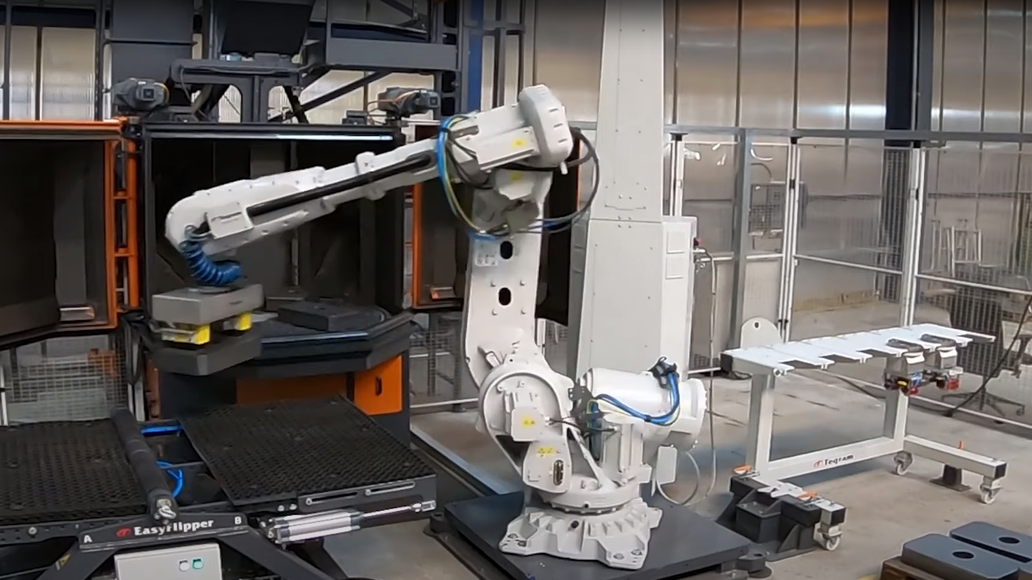

Simply place pallets with oxyful- or plama-cut parts in the robot's work area. By using EasyEye, the position of the sheet metal components is not relevant - this is recognised fully automatically.

This means that even the smallest batch sizes can be processed economically.

Fast, unbeatable quality, energy-efficient (-75%)

Increase your quality with EasyShotblast! Narrow sides are processed perfectly and there are no shadows from belts or baskets on the underside.

At the same time, the energy requirement is reduced to 25% and the fast cycle times often lead to amortisations of less than 2 years!

Technical specifications:

EasyShotblast is a solution for loading and unloading blasting machines. It is based on Teqram's modular components and can be customised to specific applications. For example, fully automatic turning can be easily integrated, as can the simultaneous deslagging and deburring of workpieces!

The centrepiece of EasyShotblast is our vision-controlled robot: the EasyBot.

An EasyBot consists of the following components:

- An EasyEye, our patented 3D vision controller

- An industrial robot manipulator with 6 axes, a reach of 3.05 metres and the ability to handle oxyfuel- and plasma-cut parts weighing up to 600 kg

- A modular base (easy to transport and place) with all electronic and safety components

- The EasyShotblast process logic that independently decides how many parts are loaded into the blast machine at the same time

- EasyIO: distributed IO and control

- Our EasyFlexibleFramework: software framework for vision-controlled robotics

- A PC-based user interface: easy to operate, no PLC required.

- Gripper change adapter (robot side) with data, electrical and pneumatic connections

- and much more...

Would you like to find out more about what unmanned, automated blasting could look like in your company?