EasyFlipper - flip heavy parts safely within seconds

The patented EasyFlipper turns sheet-metal parts within seconds. This solves a number of problems. In industry, heavy workpieces are normally turned using a crane and slings, belts or clamps. This is time-consuming, often requires a great physical effort and, above all, is dangerous. There is also a high probability that the workpiece will be scratched.

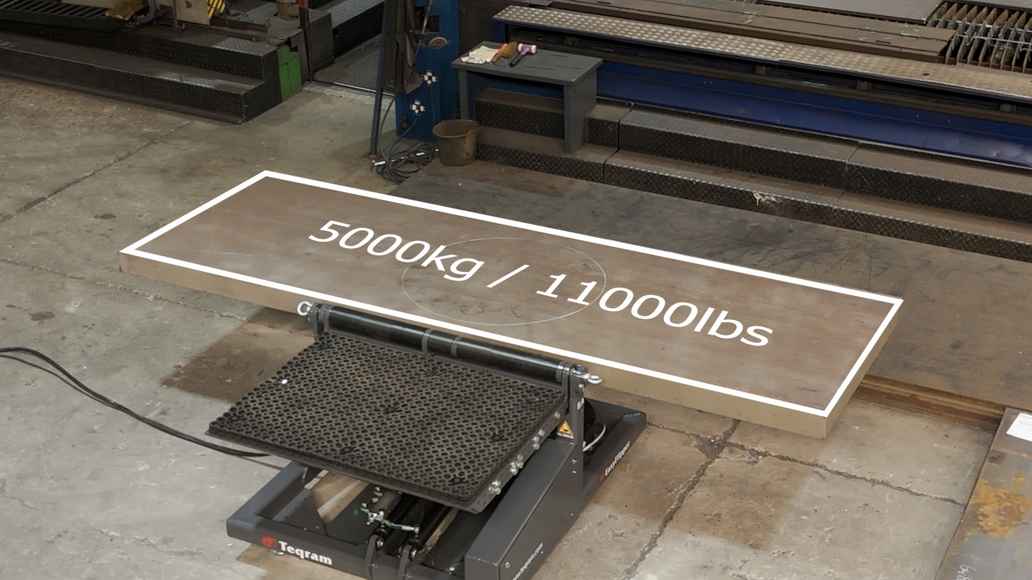

New: 5 Tons EasyFlipper

Introducing the Hydraulic EasyFlipper 5 Tons — the powerful solution for turning heavy steel plates with ease and most importantly, safety. This machine is designed to handle the toughest jobs, turning steel plates up to 5000 kg / 11000 lbs smoothly and efficiently.

The EasyFlipper plate turner is often used as a workstation for deslagging and sanding as well as a plate flipper for steel plates or sheet metal blanks. Its use as a universal turning device is particularly popular for applications where speed and safety are important.

Further informations? Let's get in touch!

Turn flame-cut, plasma-cut or laser parts quickly and safely

Typical Applications of our plate rotator:

- Safe and fast turning of heavy sheet metal components

- Turning of flame-cut parts, turning of plasma parts

- Turning heavy components in front of a machining center for processing the opposite side

- Turning laser-cut sheets next to a folding machine

- For visual inspection of the top and bottom sides in QA

- Turning of sheet metal packages - e.g. tear plates

- Turning heavy blanks to fulfill packing instructions

Gallery - EasyFlipper (Application examples - click through):

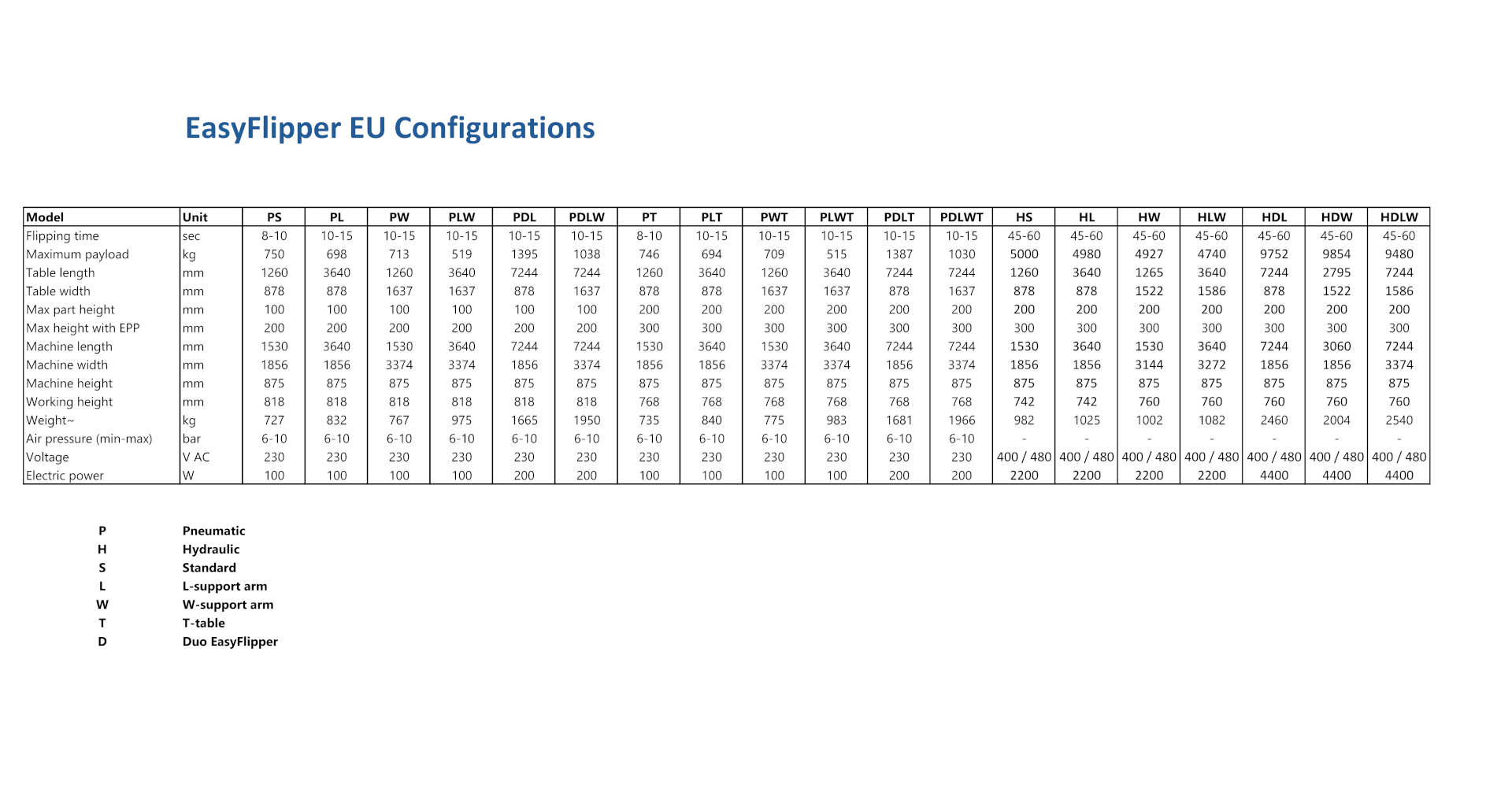

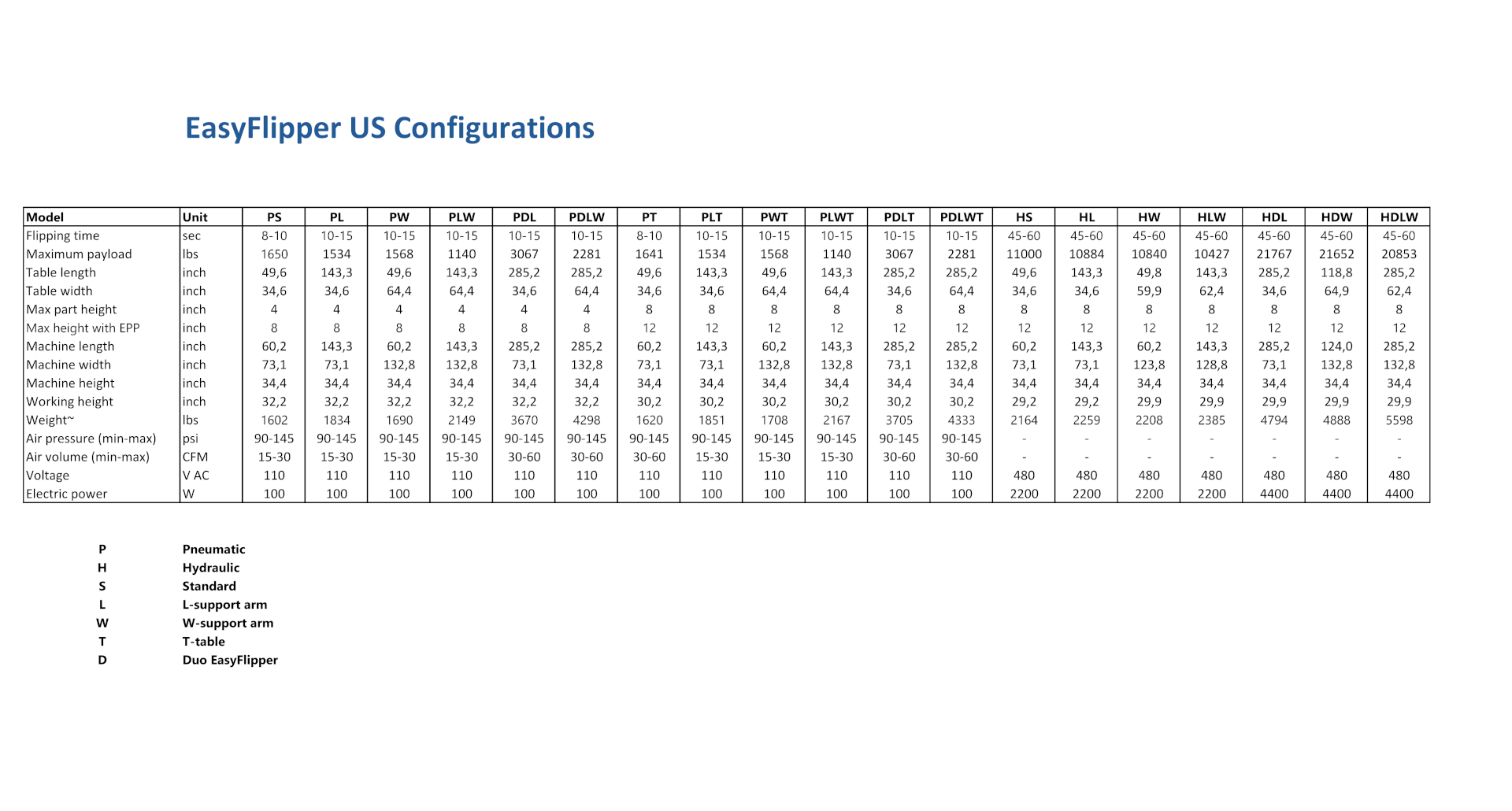

Specifications

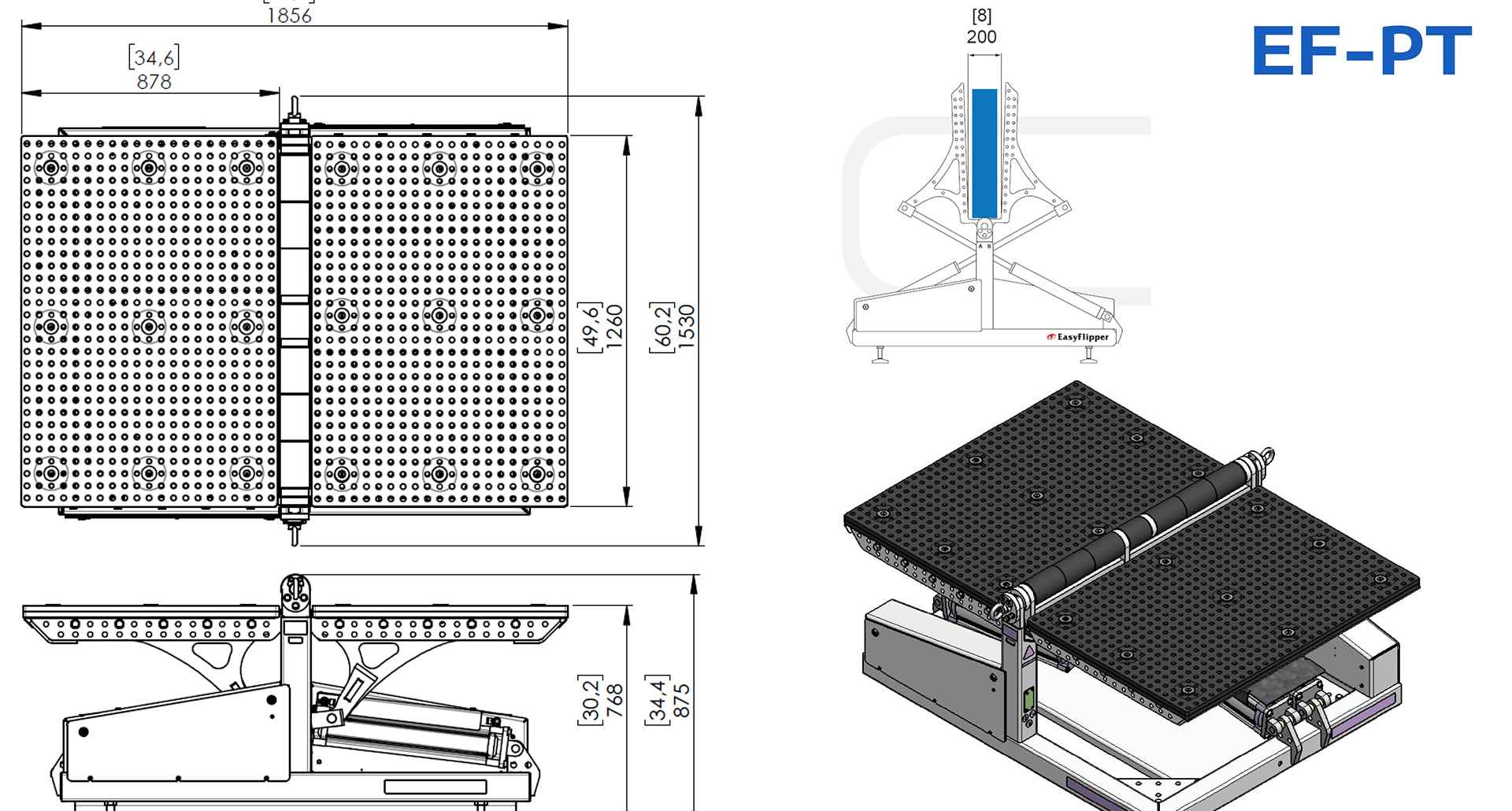

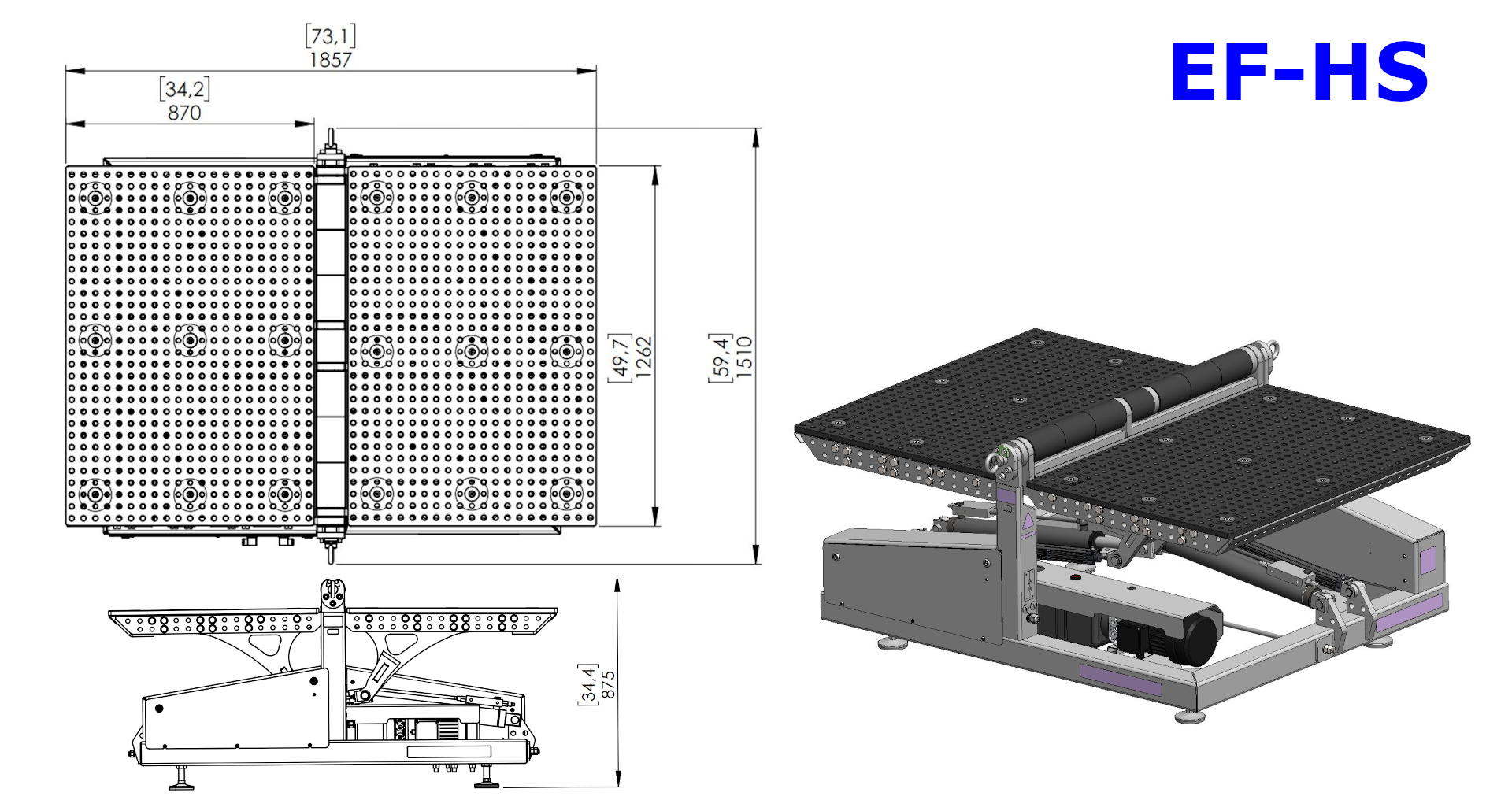

The main specifications of the standard EasyFlipper sheet metal rotator are:

- Table size: 1200 x 800mm

- Maximum part weight:

- Pneumatic EasyFlipper: 750kg / 1650lbs

- Hydraulic EasyFlipper: 5000kg / 11000lbs

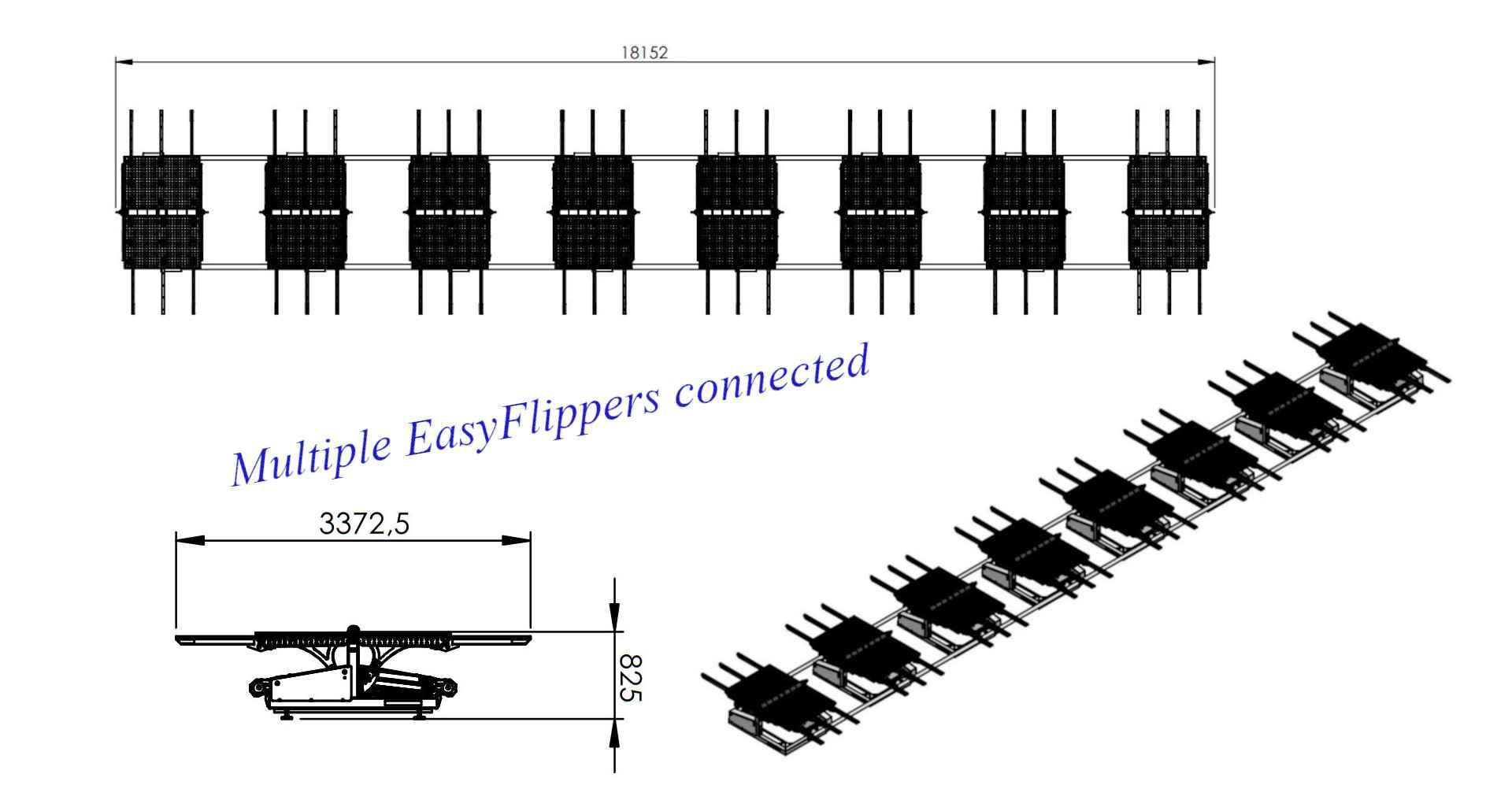

- Connected EasyFlippers: a multiple of the individual EasyFlippers

- Cycle time:

- Pneumatic EasyFlipper: 5 to 10 seconds

- Hydraulic EasyFlipper: 35 to 45 seconds

- Flipper table can be fitted with rubber mats or brushes to prevent scratches

- Easy manual control and/or integration with our vision guided robots

- 230V / 110V + 6 bar air pressure

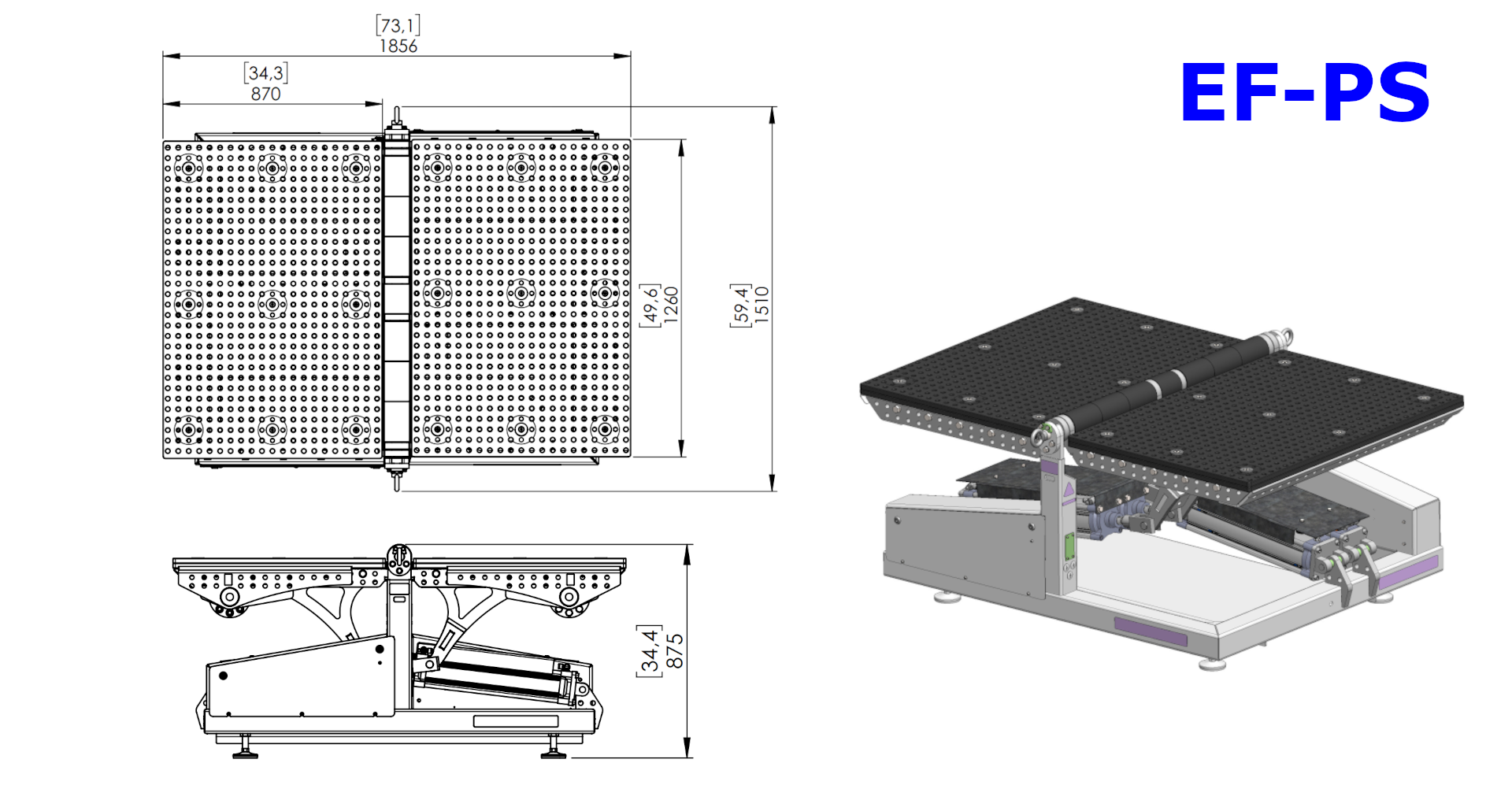

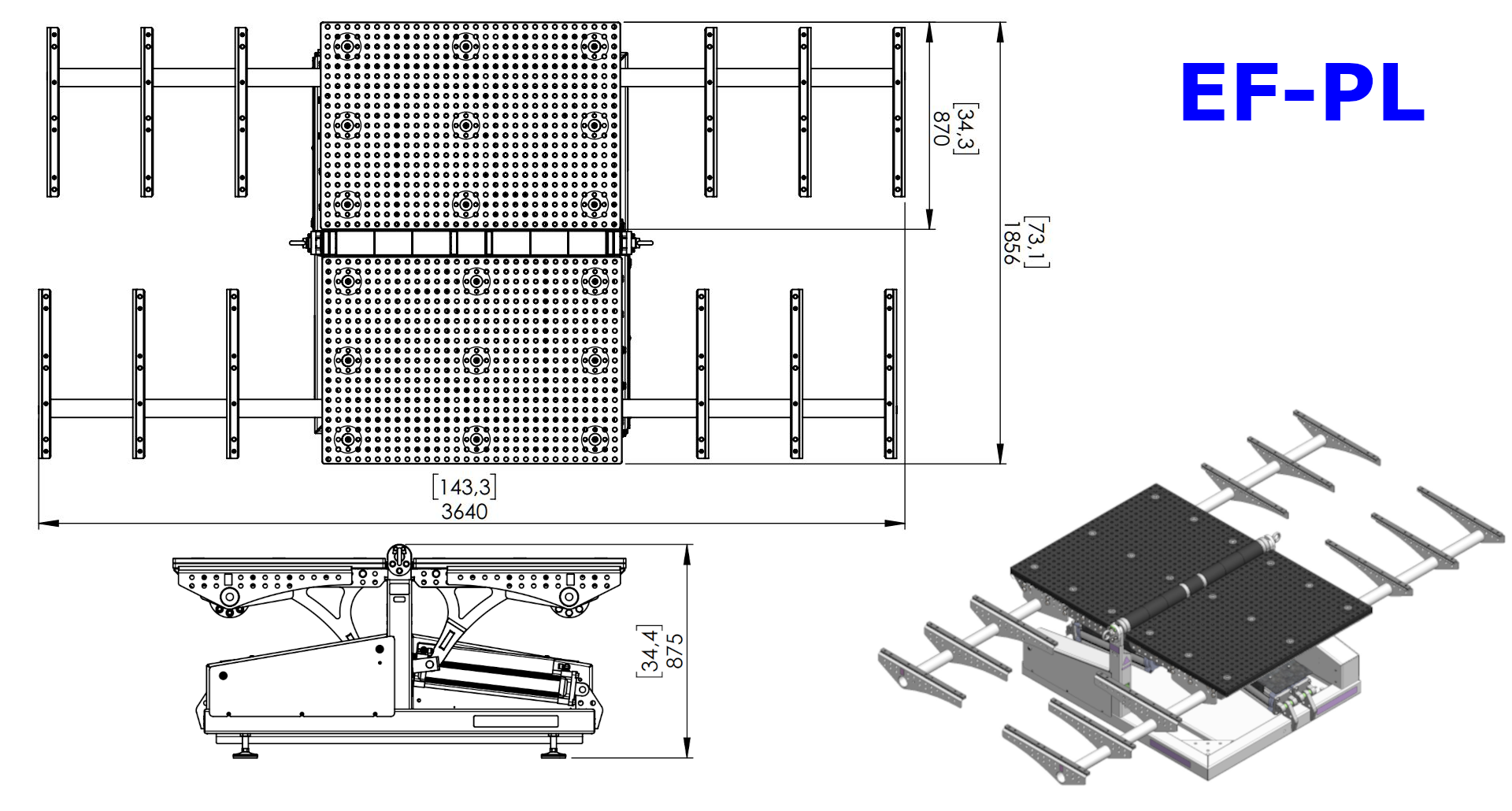

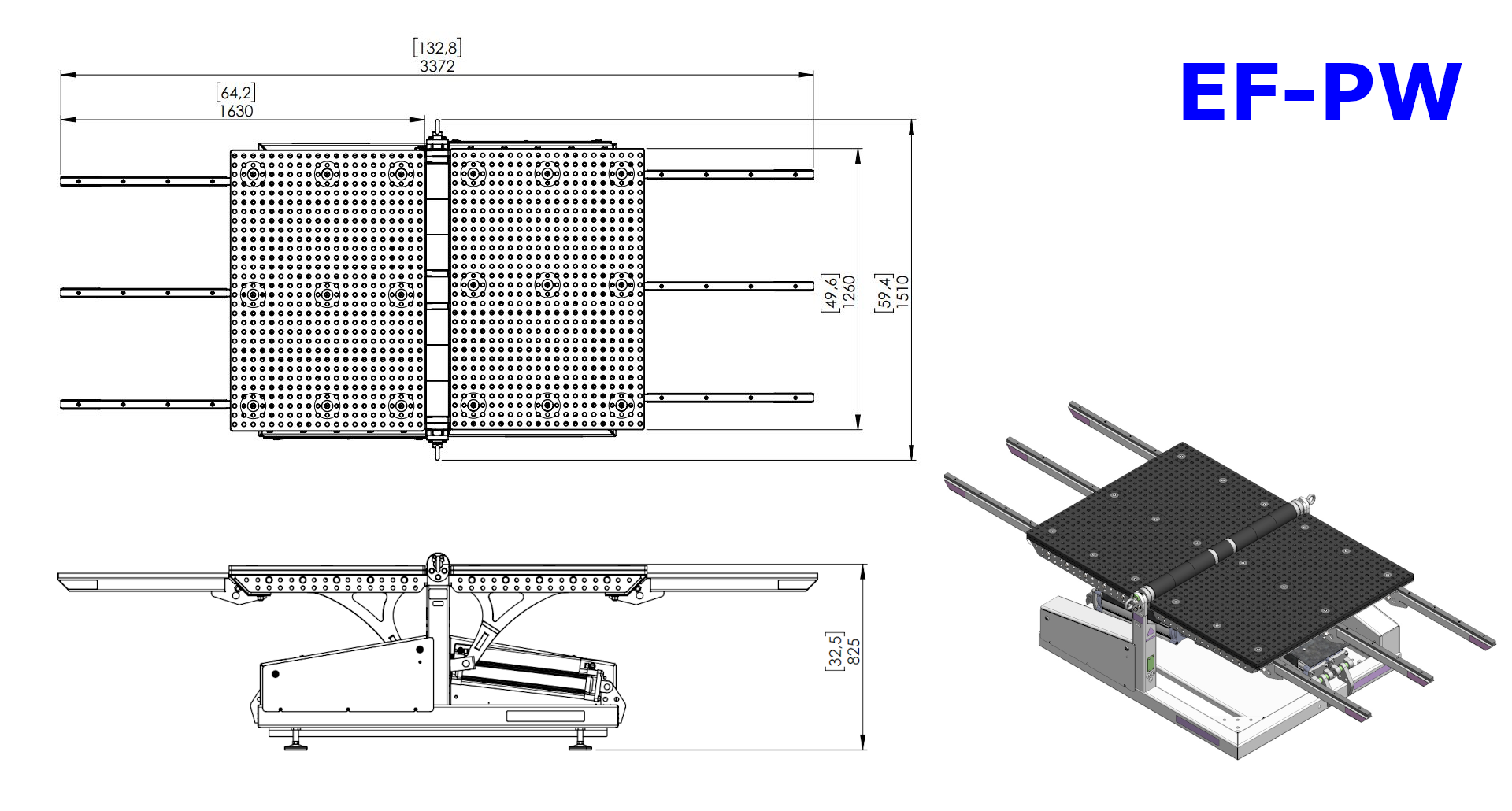

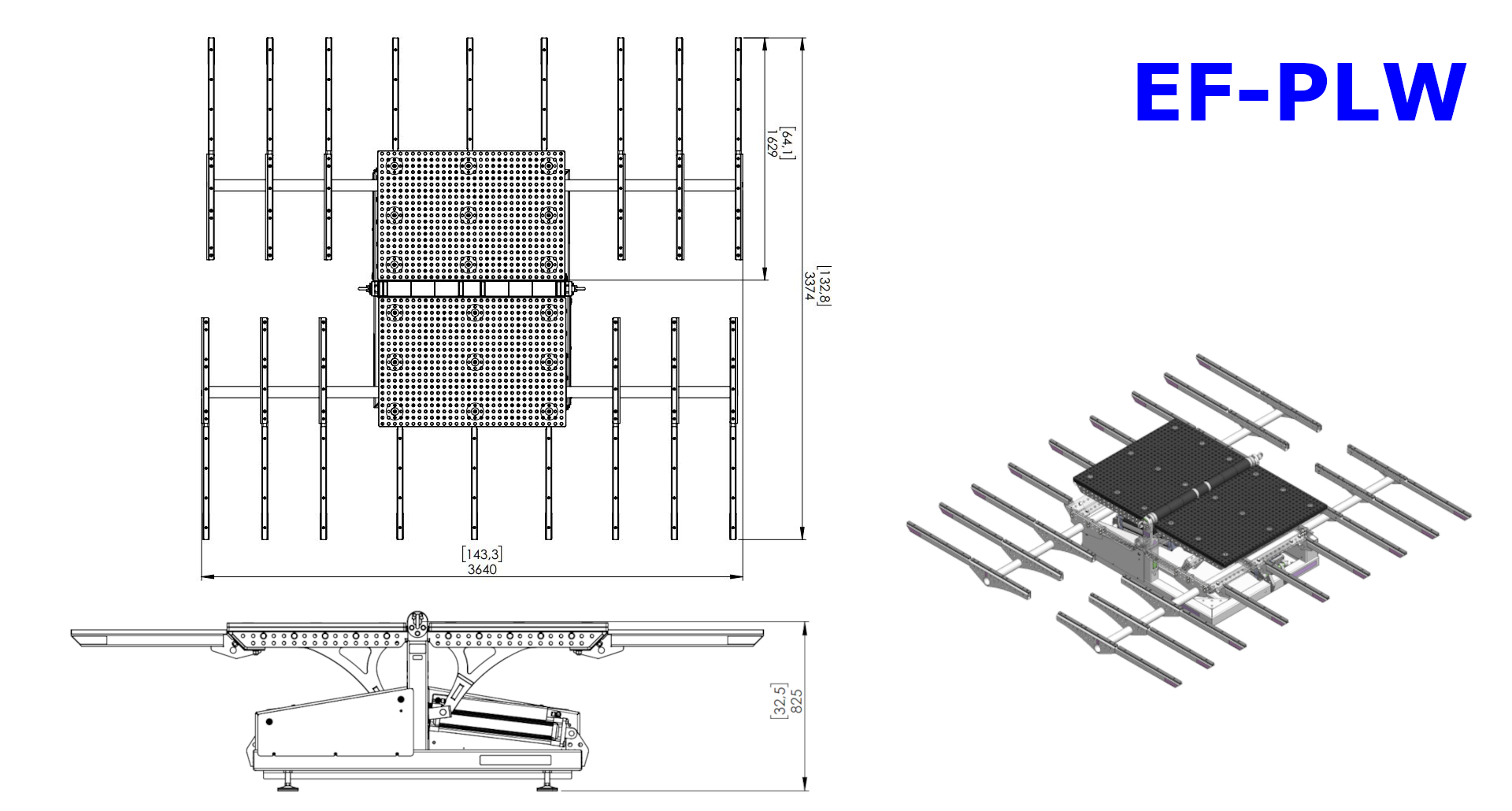

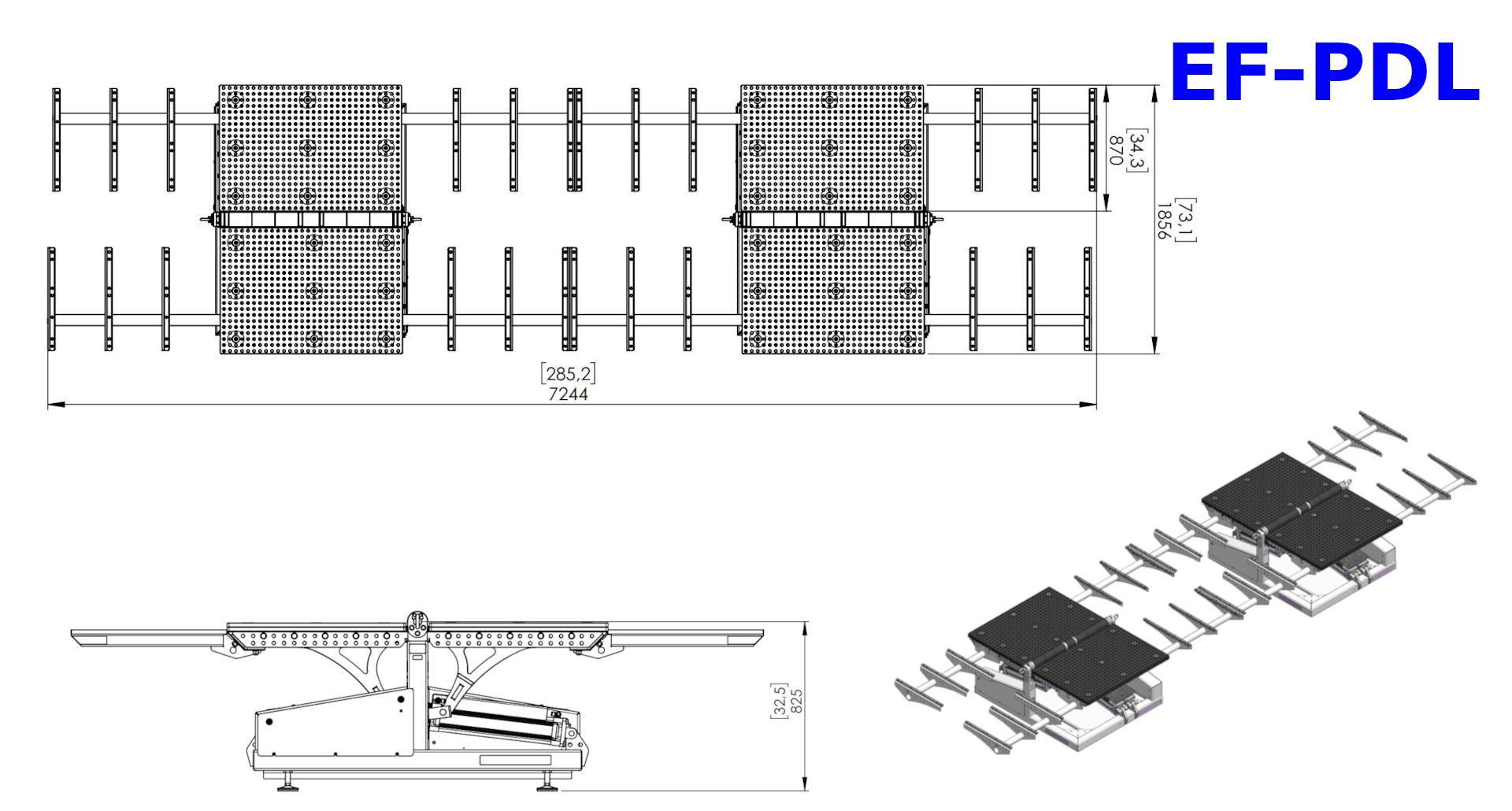

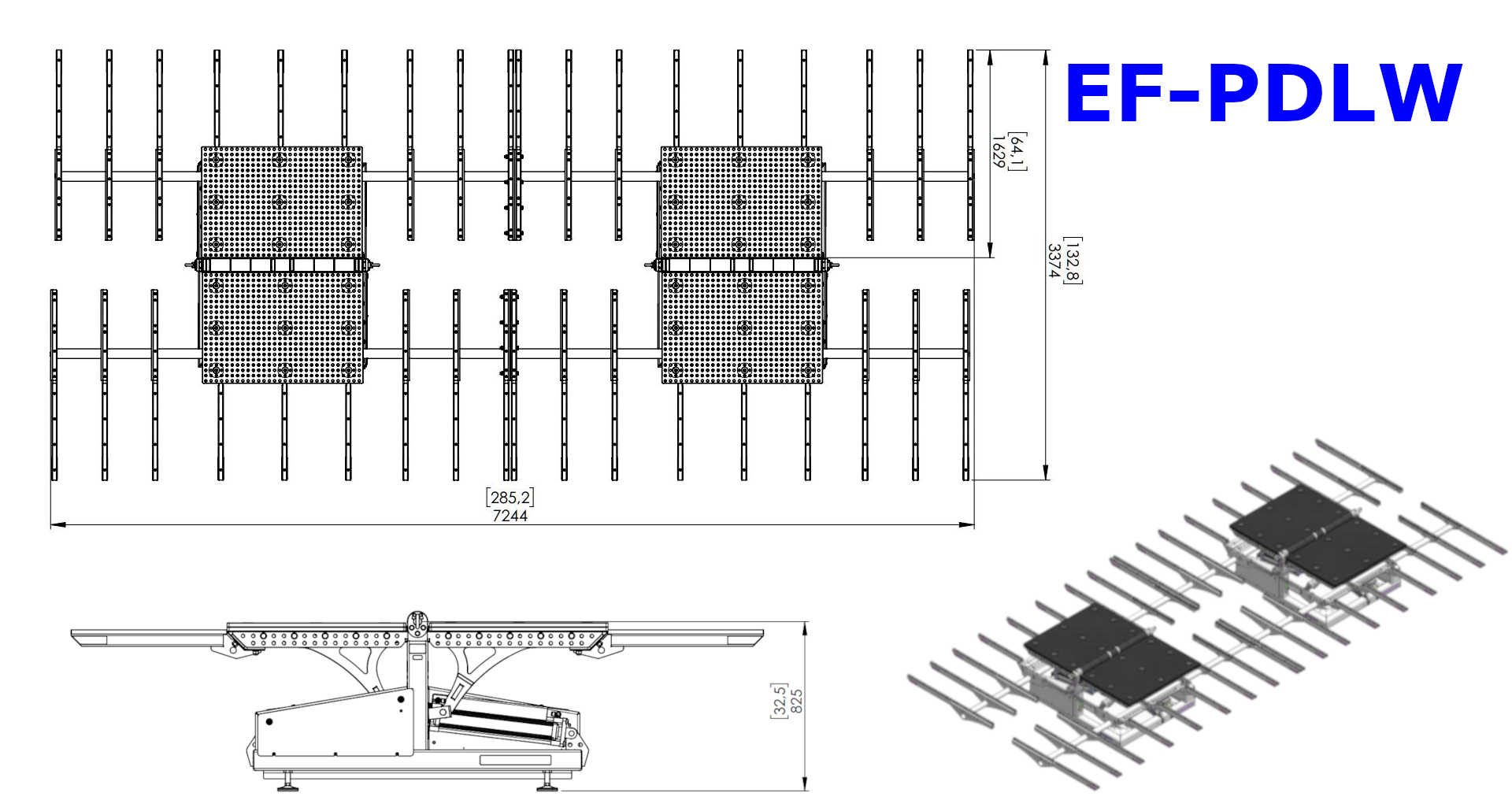

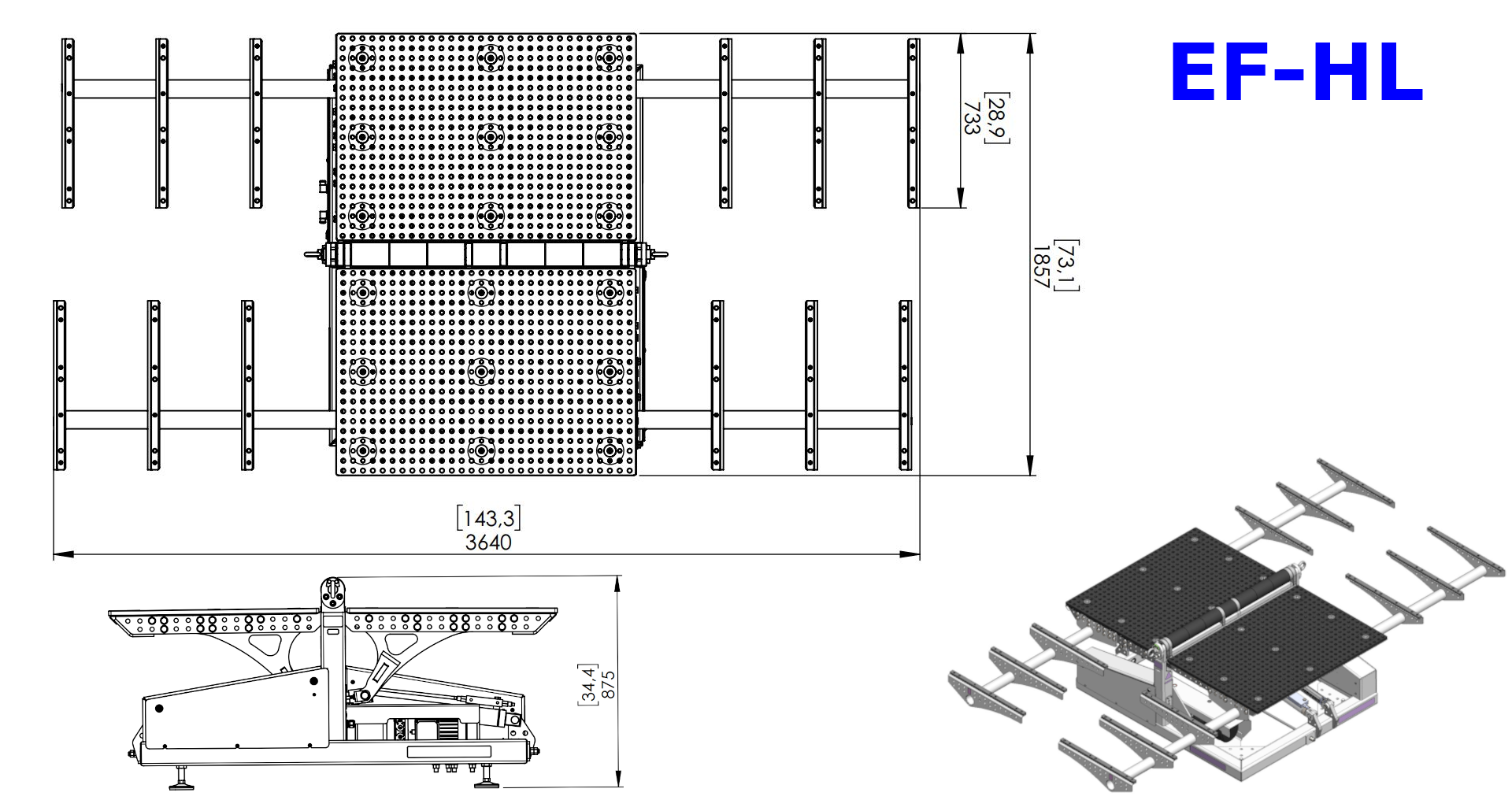

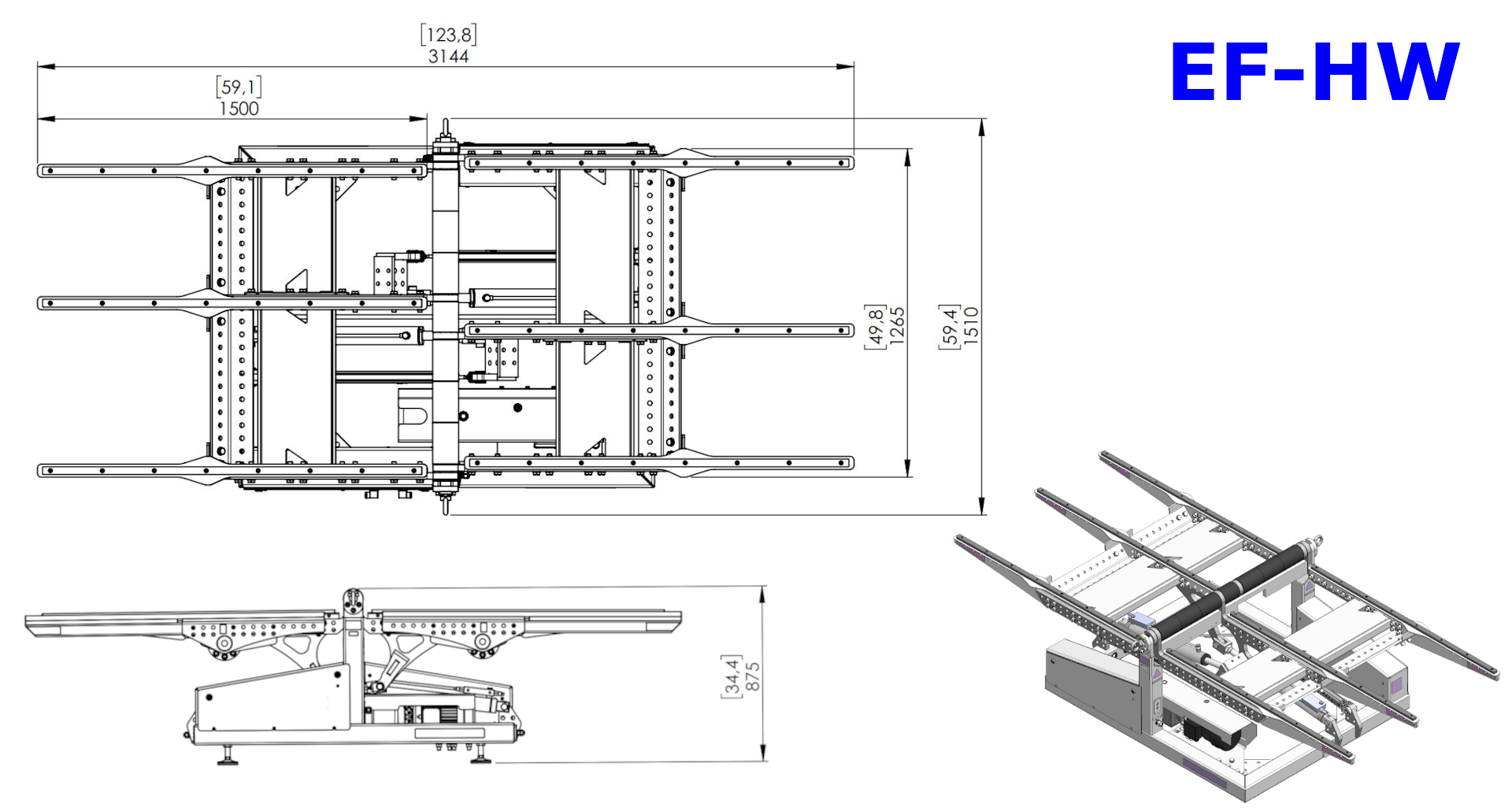

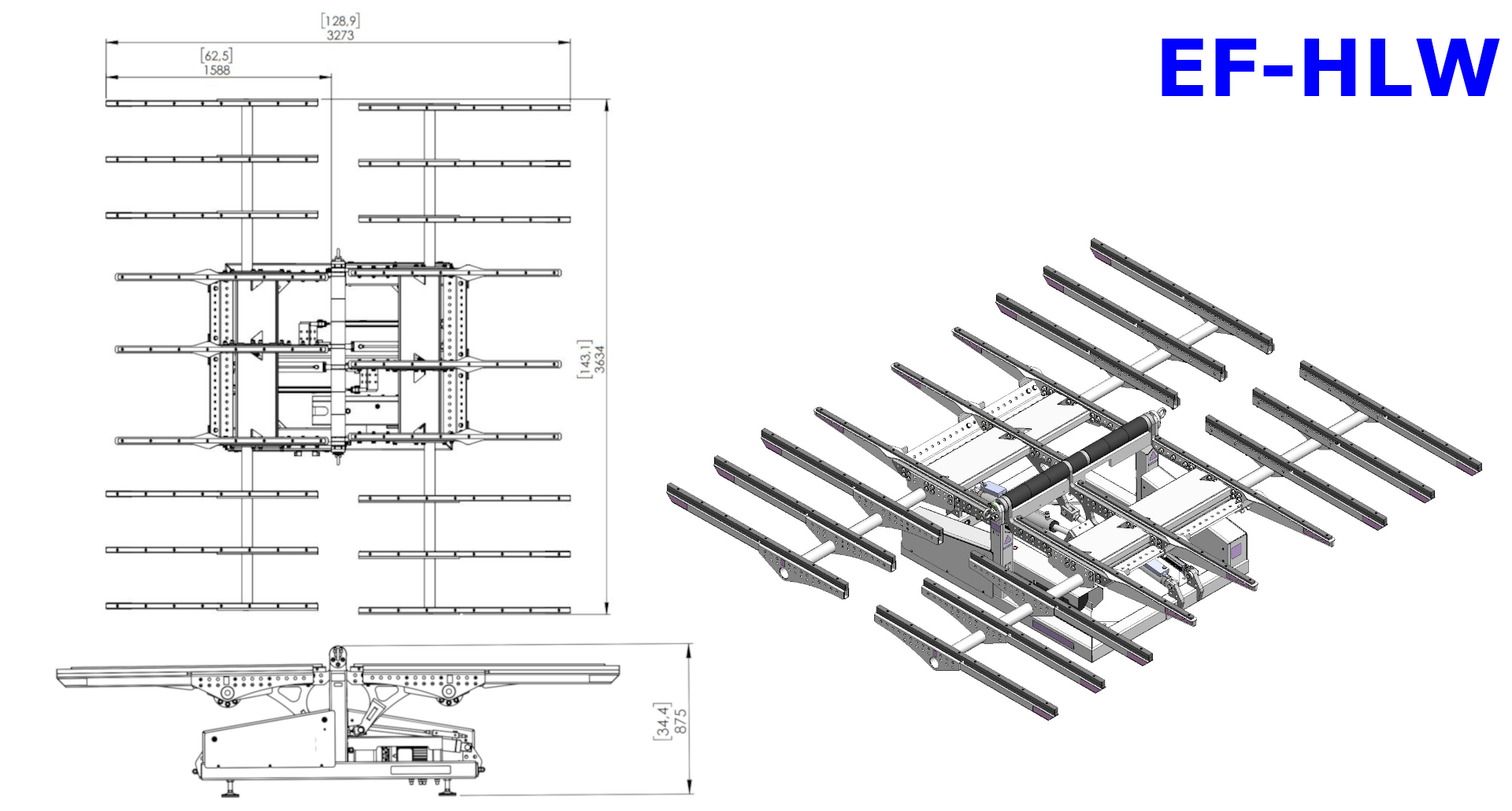

Some possible combinations with dimensions - EasyFlipper in mm [inch] (click through):

Unique Features:

If the application fits - the EasyFlipper is an absolute No-Brainer!

Speed

Turn sheet-metal parts in seconds. The fastest solution for safely turning heavy oxyfuel, plasma or laser-cut components!

Safety

"Manual" turning of sheet-metal parts (crane, hand, forklift, etc.) is very dangerous. Put safety first with the EasyFlipper sheet metal flipper!

ROI

Reduce time-consuming manual labor by automating the turning process! The competitive price of the EasyFlipper ensures an attractive ROI.

Connect 2 or more EasyFlipper for particularly long and heavy components!

Invest in your EasyFlipper!

Turn heavy components quickly and safely