Deburring Machines for Sheet Metal Processing – Automating Your Deburring Operations

Modern deburring machines reliably remove burrs, slag, and sharp edges created by flame cutting, punching, laser cutting, or waterjet cutting. The result: safe, functional, and high-quality sheet metal parts. Our solutions cover the entire sheet metal process chain — from thin sheet to heavy plate and demanding flame-cut components.

Deburring Machines Tailored to Your Requirements

When selecting the right deburring machine, material thickness, production volume, and required secondary operations play a decisive role. For series production and thin sheet metal, pass-through systems are the ideal choice. These automatic sheet metal deburring machines combine slag removal, deburring, edge rounding, and surface finishing in a single pass — fast, precise, and with extremely low cost per part.

For thick plate or plasma/flame-cut parts, powerful heavy-duty systems are required. These metal deburring machines deliver high material removal rates and defined edge rounding. If additional operations such as tab removal, blasting, pin marking, or edge-zone processing are required, the EasyGrinder extends the process and can be configured as a fully automated deburring machine.

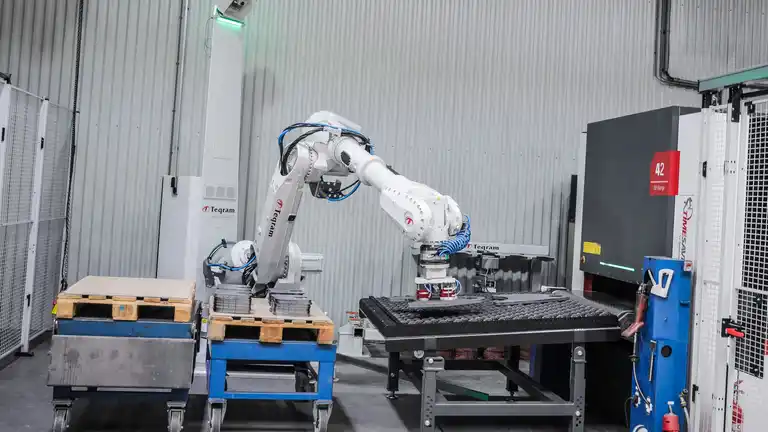

For high product variety or frequently changing batch sizes, vision-guided loading and unloading systems provide maximum flexibility and reliable handling of different geometries.

No Programming. No Teaching.

Processing Units for Different Requirements

Slag hammer

Figure: © Lissmac Maschinenbau GmbH – lissmac.com

Grinding belt module

Figure: © Lissmac Maschinenbau GmbH – lissmac.com

Request Information on Automating Your Deburring Process

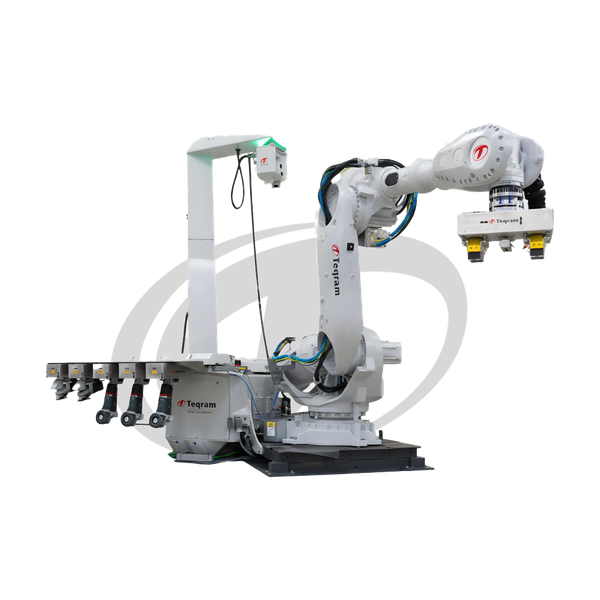

Automated Loading and Unloading for Maximum Machine Utilization.

When handling heavy or large sheet metal parts, manual loading quickly becomes physically demanding and inefficient. Automated systems provide significant relief and enable continuous, stable processes.

Our vision-guided systems reliably detect parts and safely handle components weighing 130 kg [287 lbs], 200 kg [440 lbs], or even up to 600 kg [1,323 lbs]. This ensures optimal machine utilization and significantly improves production consistency.

Advanced Processing for Thick Plate and Flame-Cut Parts

Thick plates as well as plasma- and oxy-fuel-cut components often feature heavy burrs and stubborn slag. At the same time, many flame-cut parts require additional operations beyond classic deburring.

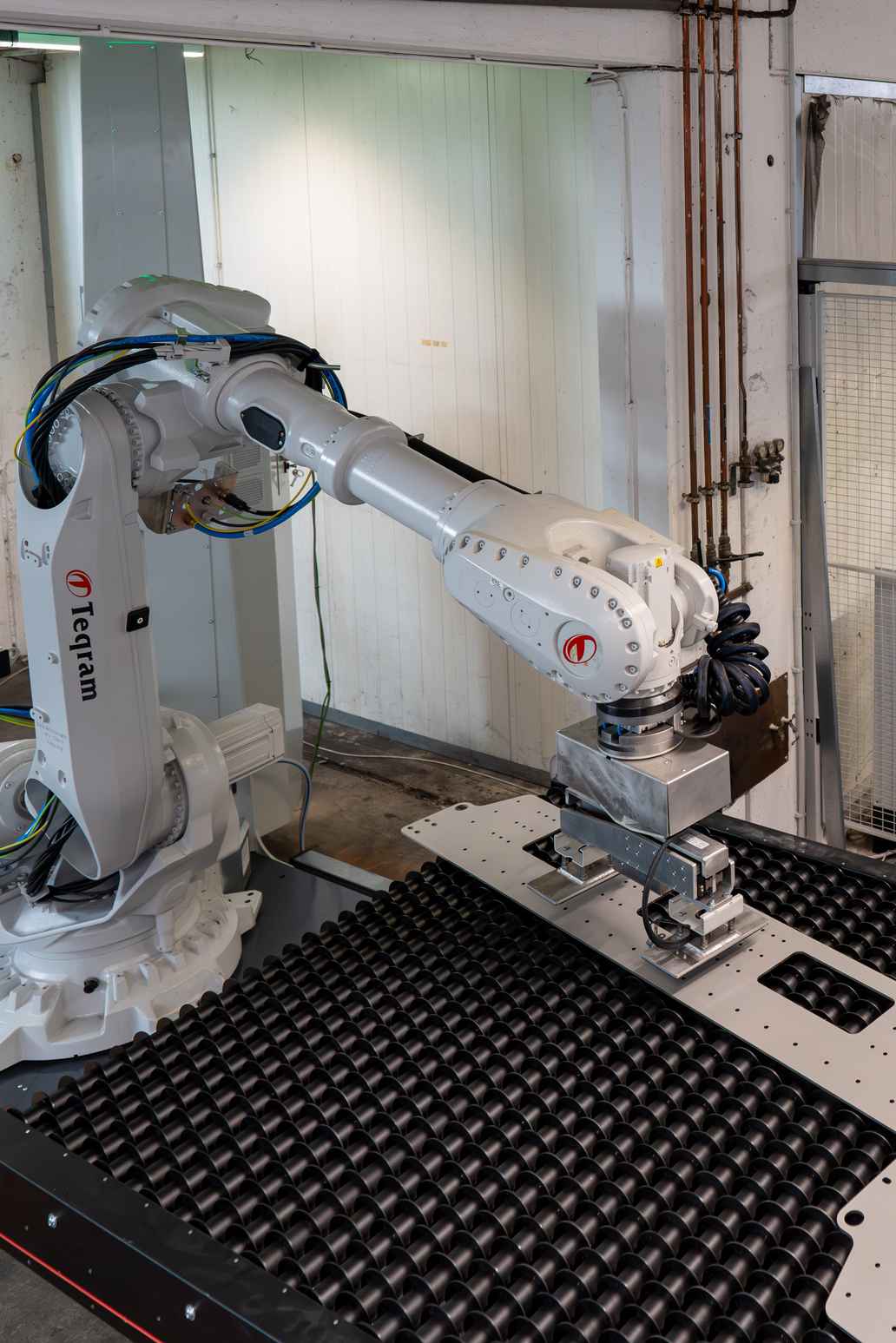

Our systems combine high-performance deburring technology with optional advanced processing steps — perfectly tailored to heavy-plate and plasma applications.

High-Performance Deburring Machines for Heavy Plate

Our heavy-duty plasma deburring machines offer high removal rates and reliably eliminate even massive burrs and slag. They also enable defined edge rounding up to approx. R2.

Two system variants are available:

Single-sided machines - Ideal for strong edge rounding and premium surface quality.

Double-sided machines - Simultaneous top and bottom processing without turning the parts — a decisive advantage for large and heavy workpieces.

Advanced Processing for Flame-Cut Parts

Many flame-cut components require additional operations such as:

- Removal of cutting tabs

- Grinding of hardened edge zones

- Blasting

- Pin marking

- Processing of complex internal and external contours

- Edge chamfering

- Additional mechanical finishing steps

These processes cannot be handled by conventional pass-through deburring machines.

With the EasyGrinder, we offer a flexible system that reliably performs these tasks and can be fully integrated into the material flow — including automated loading and unloading. The result is a continuous, highly efficient overall process for demanding thick-plate and flame-cut parts.

Technology and Cost Efficiency

Pass-through deburring systems stand for maximum speed, consistent processing quality, and low cost per part. Especially in medium and large series production, they offer significant economic advantages.

Economic Benefits

- High processing speed

- Double-sided processing without part turning

- Reduced labor requirements

- Stable and repeatable results

- Lower operating costs through optimized abrasives and energy use

Expandability for Complex Requirements

Varying geometries and additional processing steps can be seamlessly integrated using the EasyGrinder, creating a flexible and future-proof finishing process.

Integration into Existing Production Lines

Our systems integrate easily into existing material flows, conveyor systems, and MES environments. Production data and process parameters can be documented and analyzed — ensuring transparency and consistent quality assurance.

Jetzt EasyGrinder & EasyDebur in Ihre Prozesse integrieren!

Automatisieren Sie Ihren Betrieb mit Teqram Entgrat-Roboter-Lösungen

Thin Sheet and Fine Sheet Metal Processing

Laser-cut and punched thin-sheet parts often feature delicate burrs and sensitive edges. Our sheet metal deburring machines for thin material are specifically designed to remove these precisely and create clean, defined edges.

They provide:

- Reliable burr removal

- Defined edge rounding

- Reproducible results at high production volumes

- Ideal surface preparation for painting and coating

Precision clamping and guiding systems prevent deformation — a crucial advantage when working with thin materials. Depending on the application, machines can be configured single- or double-sided.

This also makes them ideal deburring machines for small parts and high-volume production.

Typical Applications

Our deburring machines are ideally suited for:

- Laser cutting: deburring, oxide removal, surface preparation

- Plasma cutting: slag removal, edge rounding, surface finishing

- Punching: elimination of sharp edges, defined rounding

- Waterjet cutting: burr removal, edge rounding

- Foil-coated sheets: deburring without damaging protective film

Materials include steel, stainless steel, aluminum, and many non-ferrous metals and alloys — all processed reliably and safely.

Why Deburring Is Critical – and How We Deliver the Right Solution

Properly deburred and rounded sheet metal parts improve workplace safety, enhance assembly and functionality, ensure coating adhesion, increase corrosion resistance, and deliver a premium visual finish.

To meet these requirements, we provide customized deburring solutions: high-performance pass-through machines, specialized modules for thin and thick sheet, automated loading and unloading, and advanced processing with the EasyGrinder

We integrate all components into complete solutions — including installation, commissioning, and technical support.

Other Robotic Solutions

Discover additional Teqram automation solutions that may also be relevant to your production.

With EasyGrinder, you achieve consistently precise grinding results—powerful, uniform, and reliable. Ideal for series production and demanding parts, EasyGrinder ensures perfect surface finishing and consistent material removal, all without manual effort.

EasyMillDrill automates your machining processes. Workpieces weighing up to 600 kg [1,323 lbs] are placed into the machining centers and the program is started automatically. This includes flipping the parts, optional re-feeding, and external blowing-off of chips and coolant. This enables unmanned shifts and ensures perfect machine utilization.

Teqram’s robotic solutions bring automation to a new level—flexible, reliable, and individually adaptable. Whether handling, assembly, or specialized processing, here you can explore our entire range of robotic solutions.

Request Your Deburring Machine Now

We deliver customized automated deburring machines for your parts, materials, and production processes. From initial analysis to commissioning, we support you with expertise, service, and passion for engineering.

Whether you need a compact standalone solution or a fully automated robotic deburring machine cell — we implement your requirements precisely and reliably.

Use our contact form for your inquiry. Our team will advise you personally and solution-oriented. We look forward to turning your ideas into reality.