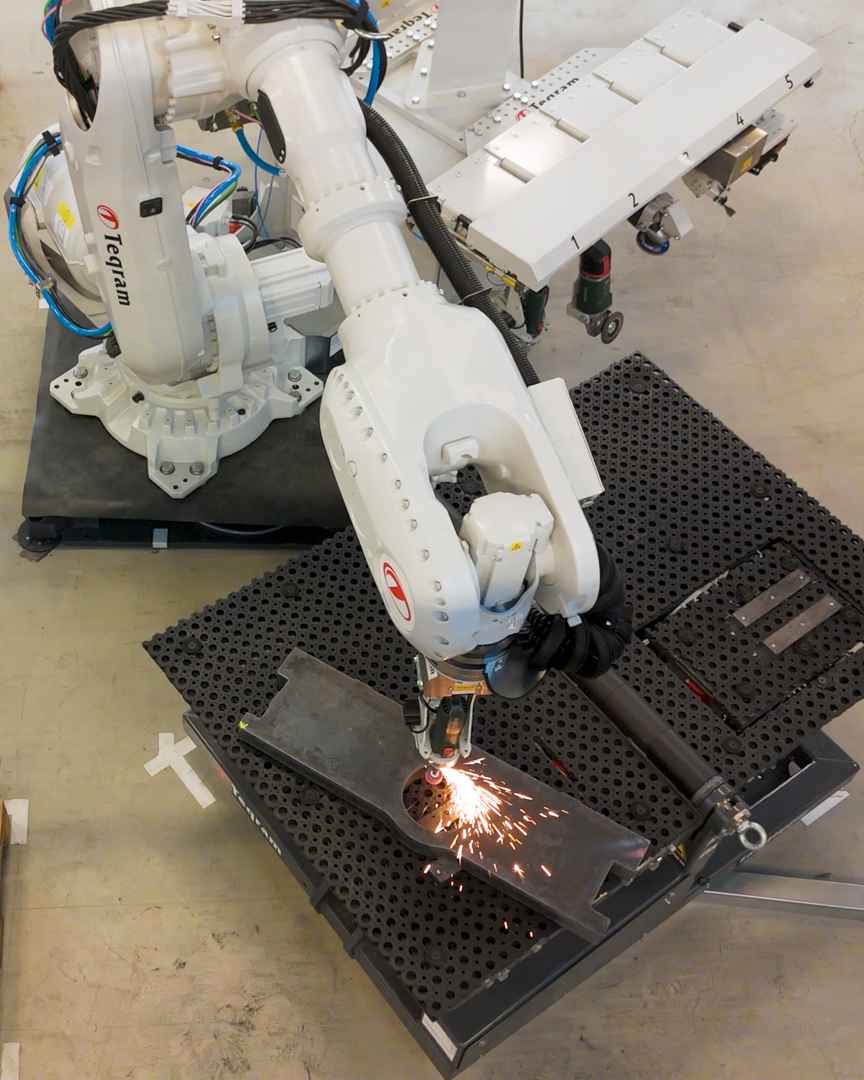

EasyGrinder – The AI-Powered Grinding Robot for Flame-Cut, Plasma, and High-Power Laser Parts – No Programming Needed

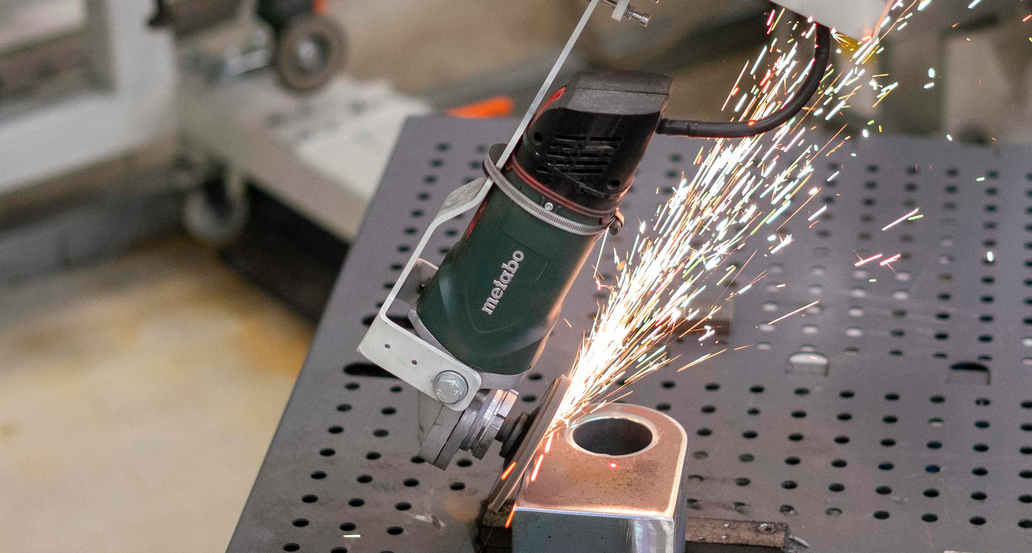

Grinding burned parts is physically demanding, monotonous, and carries a high risk of injury. With its advanced robotic grinding automation, the EasyGrinder grinding robot from Teqram takes over this task for you—fully automatically and without any programming. This is made possible by intelligent vision technology combined with AI, enabling highly reliable and consistent automated grinding processes.

From removing slag to standardized surface preparation according to DIN EN ISO 8501-3 (preparation grade P3) and DIN EN ISO 12944-3—all work steps are performed with process reliability and full reproducibility. Suitable for flame-cut parts, plasma cuts, and high-performance laser cuts.

EasyGrinder - Processing Capabilities

The EasyGrinder was specifically developed for flame-cutting operations and delivers 100% consistent, high-quality processing—independent of operator condition, experience, or the availability of skilled personnel. The operator simply selects the desired processing quality from predefined recipes. The software determines which tools and grippers are required and changes them fully automatically.

A reliable solution for flame-cutting companies that prioritize efficiency, safety, and competitiveness.

No programming. No teaching.

PROCESSING OPTIONS WITH ROBOTIC GRINDING

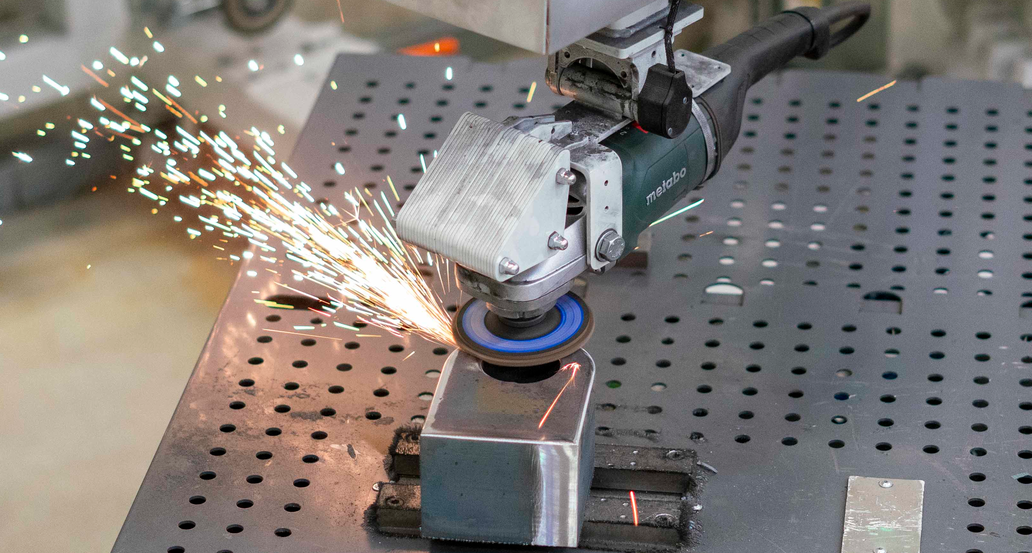

- Slag removal – reliable removal of slag on thermally cut edges

- Edge breaking or rounding – including radius R2 and, optionally, larger radii (e.g., R3) depending on customer requirements

- Preparation grade P3 according to DIN EN ISO 8501-3 – including post-processing of the cut surface and defined edge rounding

- Removal of oxide and scale layers – especially on cut surfaces typically produced by plasma, oxy-fuel, or high-power laser cutting

- Grinding of heat-affected edge zones – for homogeneous blasting results

- Removal of burn-in and lead-in burrs – clean removal of excess material

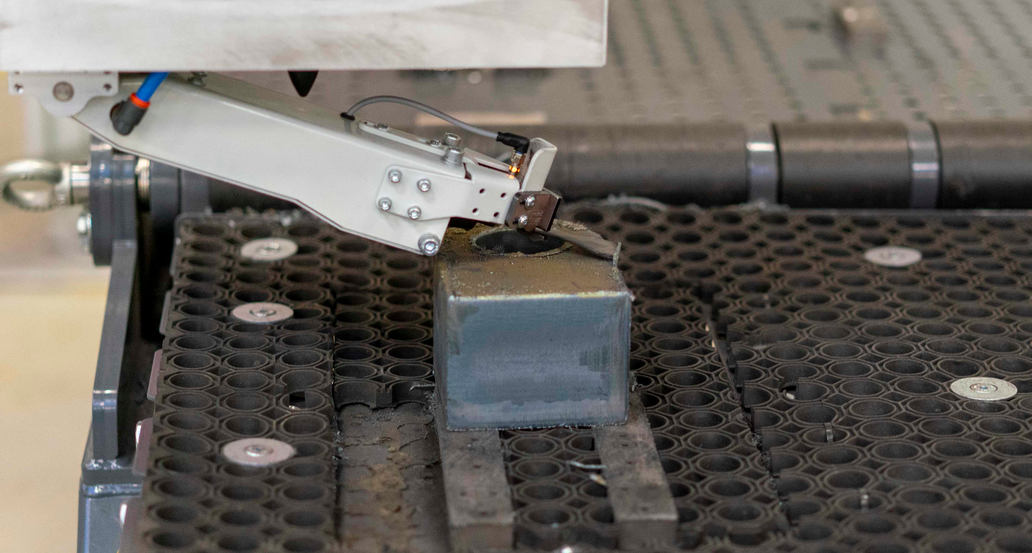

- Deburring or countersinking of holes – precise removal of burrs or the creation of a countersink

- Grinding of bead chains – on the upper narrow side of oxy-fuel-cut parts

- Creating chamfers – precise machining of bevelled edges for weld preparation

Optional additional processes – automated operations such as blasting or stamping can also be seamlessly integrated

Contact us now for your customized robotic solution!

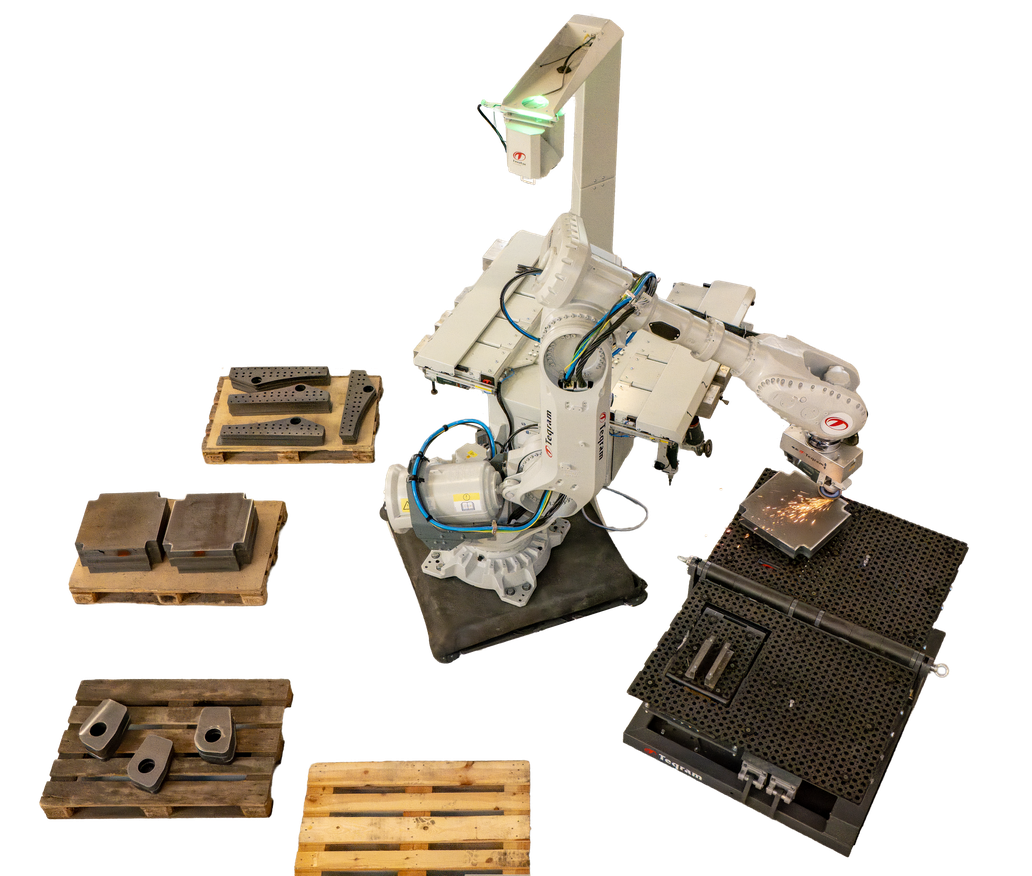

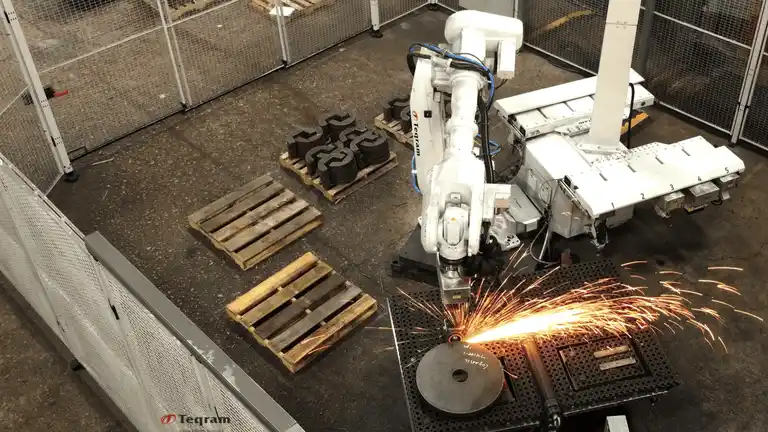

Application Examples for the EasyGrinder

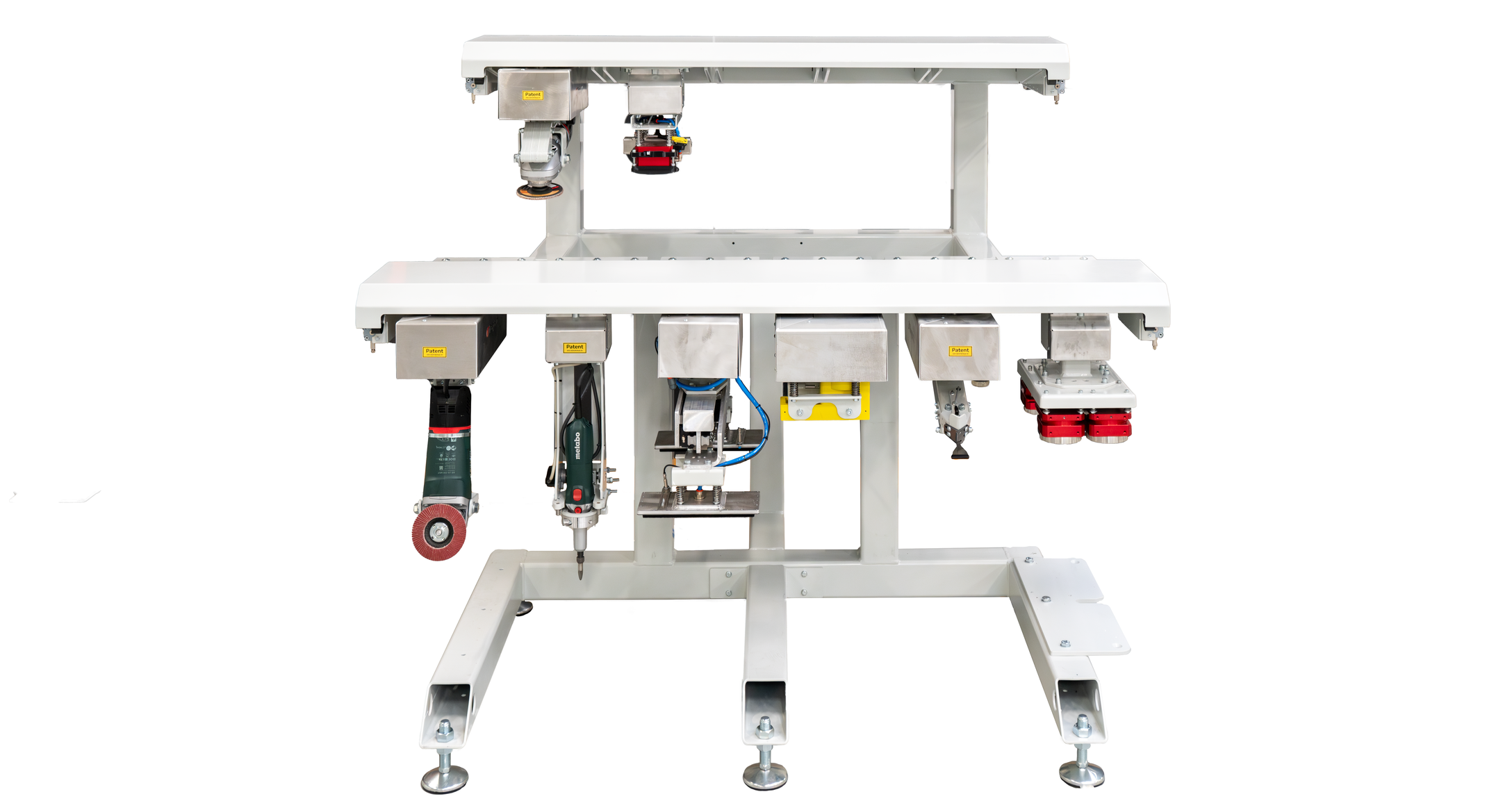

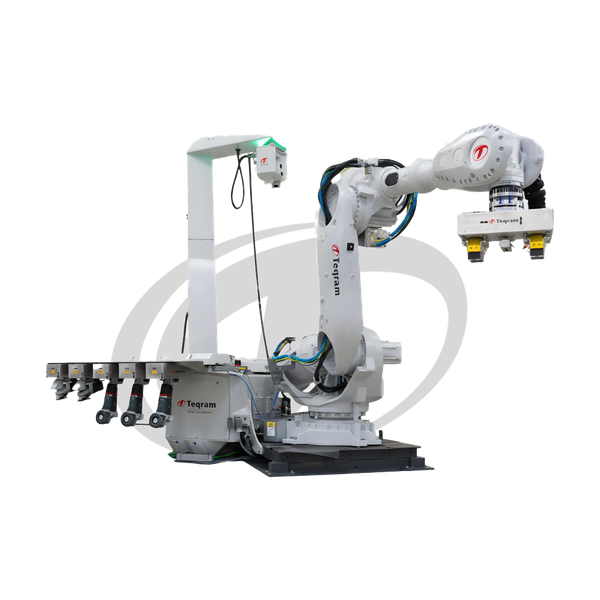

EasyGrinder – Tooling Options and Configurations

The EasyGrinder Models – The Right Solution for Every Application

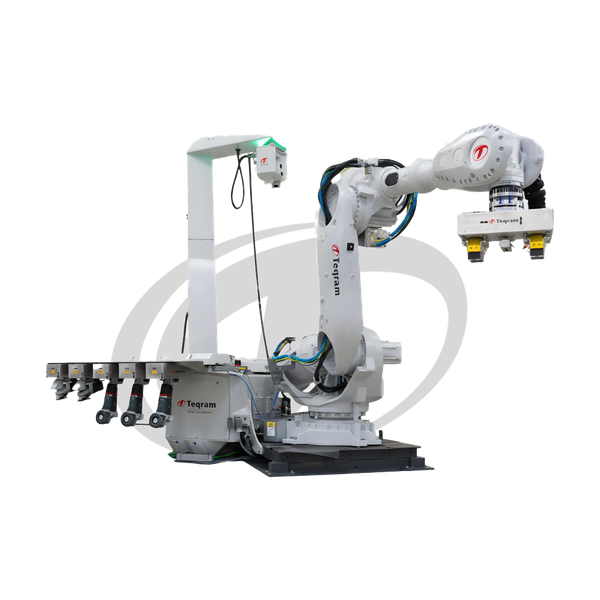

EasyGrinder 200

Handles 90% of typical flame-cut, plasma-cut and high-power laser parts

Max. workpiece weight: 200 kg [440 lbs]

Max. workpiece dimensions:

• 1,100 × 700 mm [43.3 × 27.6 in]

• 1,300 × 500 mm [51.2 × 19.7 in]

• 1,600 × 200 mm [63.0 × 7.9 in]

System function: The robot performs both handling and processing.

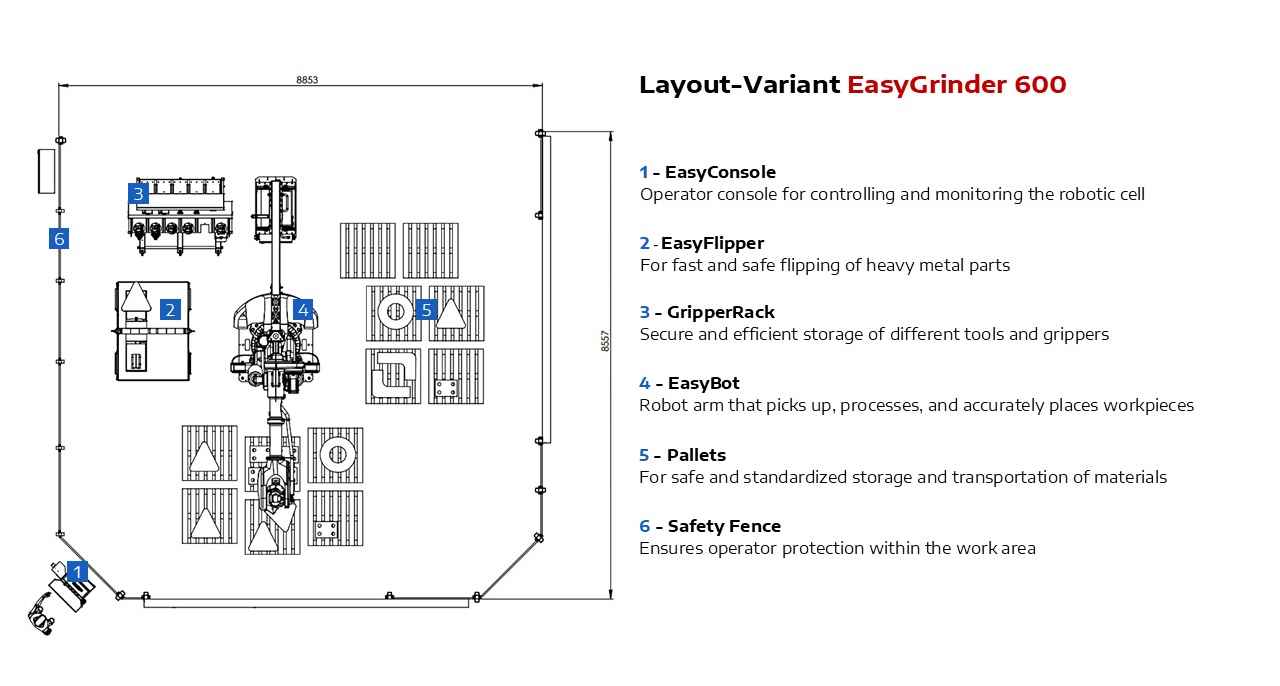

EasyGrinder 600

For heavy workpieces and large formats

Max. workpiece weight: 600 kg [1,323 lbs]

Max. workpiece dimensions:

• 4,000 × 1,000 mm [157.5 × 39.4 in]

• 3,000 × 1,500 mm [118.1 × 59.1 in]

• 2,000 × 2,000 mm [78.7 × 78.7 in]

System function: The robot performs both handling and processing.

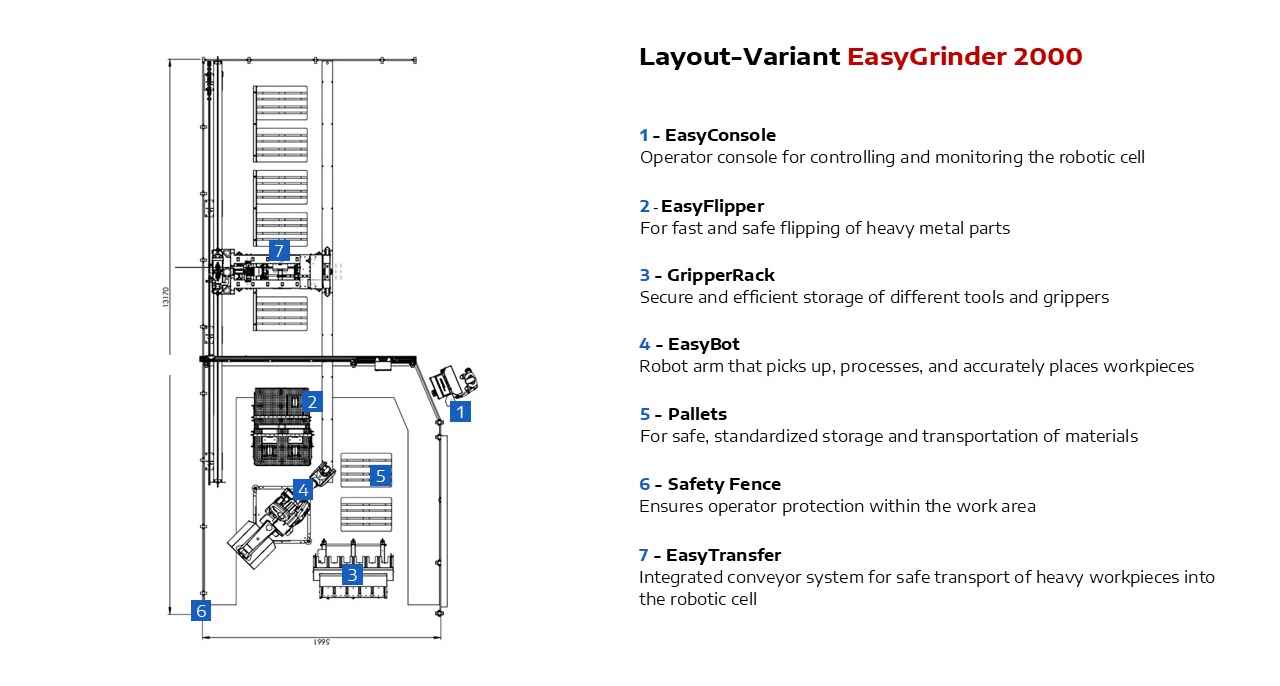

EasyGrinder 2000

For extremely heavy workpieces with automated loading

Max. workpiece weight: 2,000 kg [4,409 lbs]

Max. workpiece dimensions:

• 1,700 × 600 mm [66.9 × 23.6 in]

System function: The robot performs the processing; handling is managed via the integrated Easy-Transfer System.

Integrate the EasyGrinder into your workflow today!

Boost your productivity with Teqram’s automated grinding robot.

Various Layout Configurations of the EasyGrinder

Whether compact cut parts or ton-heavy large components—With three powerful model variants, the EasyGrinder offers maximum flexibility in weight, format, and level of automation. Ranging from 200 kg to 2,000 kg, each model is precisely tailored to specific requirements. This wide range ensures flexible processing from small cut parts to large-scale components without any difficulty.

Advantages of the EasyGrinder Robotic Grinding System

No Programming Required – Thanks to Vision Technology and AI

The EasyGrinder automatically detects part geometries—completely without programming, teach-in, or CAD data. This is made possible by an intelligent combination of time-of-flight sensors, HD cameras, and 3D vision systems. Position, shape, and size of the cut parts are captured autonomously, and the robot automatically generates the correct processing routine. This enables direct processing of changing part types without any setup time—an essential advantage over classic systems that require extensive programming.

24/7 Operation for Your Production

With autonomous part detection, automatic tool monitoring, and recipe-based control, the EasyGrinder is ideal for around-the-clock operation—delivering consistent quality and predictable output. Its robust design and high process reliability further support continuous industrial use.

Standard-Compliant Surface Processing According to ISO

The EasyGrinder meets the highest requirements for thermally cut edges, including:

- Preparation grade P3 according to DIN EN ISO 8501-3

- Edge rounding to radius R2 or R3

- Post-processing of cut surfaces and removal of heat-affected edge zones

Even processes that are nearly impossible to perform manually can be performed reliably and in full compliance with standards.

Recipe-Controlled Processing Quality

Processing recipes define precisely which quality level is required. One part may only need slag removal, while another may require complete slag removal, edge rounding, and stamping—fully automated and reproducible. This provides maximum flexibility for changing customer requirements without any setup effort.

Increase Productivity – Reduce Costs

- No manual programming or teaching required

- Predictable output across three shifts

- No additional rework, no scrap

- Automatic tool monitoring reduces downtime

Optimized throughput, even with high part variety

100 Percent Consistent Quality

The EasyGrinder delivers uniform grinding results regardless of operator skill or condition. Even distorted workpieces are processed optimally thanks to adaptive pressure control (patented integrated tolerance compensation). Every step is performed with perfect consistency.

Cost Efficiency and Long-Term Investment Security

With skilled labor shortages increasing, the EasyGrinder offers a powerful alternative to manual work. It replaces monotonous and physically demanding tasks with a cost-effective, scalable, and future-ready solution.

Modular Expansion – Tailored to Your Needs

The EasyGrinder can be seamlessly integrated into existing production workflows and individually adapted through modular extensions:

- Automatic tool changers

- Integrated automatic flipping unit

- Custom gripper solutions

- Optional enclosures for dust and noise protection

Integrate the EasyGrinder into your processes now!

Automate your operations with the Teqram grinding robot.

Technical Features

The EasyGrinder is our solution for slag removal, deburring and edge rounding, as well as the removal of oxide layers.

- Parts are supplied to the robot on Euro pallets.

- Supply in containers such as mesh boxes is also possible.

- Product weights of up to 200 kg [440 lbs] / 600 kg [1,323 lbs] can be picked up and handled by the robot (for high-autonomy systems).

- Parts weighing up to 2,000 kg [4,409 lbs] are fed to the robot via the EasyTransfer System.

- The PC-based user interface is extremely easy to use.

- No special expertise and absolutely no programming are required.

- Required gripper and tool changes are carried out automatically.

- Various standard EasyGripper options are available; customer-specific grippers can be manufactured on request.

- A wide range of standard and cost-effective grinding tools can be used.

Additional Robotic Solutions

Below you will find further automation solutions from Teqram that may also be relevant for your operations:

EasyDebur automates your through-feed deburring machine and reduces the workload for your employees. Ideal for series production and demanding workpieces—including automatic flipping of parts, provided that one-sided deburring machines are used.

EasyMillDrill EasyMillDrill automates your machining processes. Workpieces weighing up to 600 kg [1,323 lbs] are placed into the machining centers and the program is started automatically. This includes flipping the parts, optional re-feeding, and external blowing-off of chips and coolant. This enables unmanned shifts and ensures perfect machine utilization.

Teqram’s robotic solutions bring automation to a new level—flexible, reliable, and individually adaptable. Whether handling, assembly, or specialized processing, here you can explore our entire range of robotic solutions.

Automated Grinding with Teqram – Request Your Non-Binding Consultation Now

Are you looking to automate your grinding processes and need a solution that integrates seamlessly into your production environment? Teqram develops intelligent grinding robots that process your parts efficiently, safely, and with consistently high quality—without any programming effort.

From the first consultation to final commissioning, we support you with technical expertise and many years of practical experience. Our mission: increasing efficiency, ensuring quality, and simplifying processes—reliably and economically.