Vision-Guided Robotics

powered by AI

Your Expert in Vision-Guided Robotics Powered by AI

Automation the way you want it.

Our AI-driven robotic systems automatically detect, pick, and process parts — with no manual programming or teach-in required.

For plate and sheet metal processing, machine loading and unloading, grinding, and deburring. Rethinking efficiency.

No Programming. No Teaching.

See a selection of our customer success stories below.

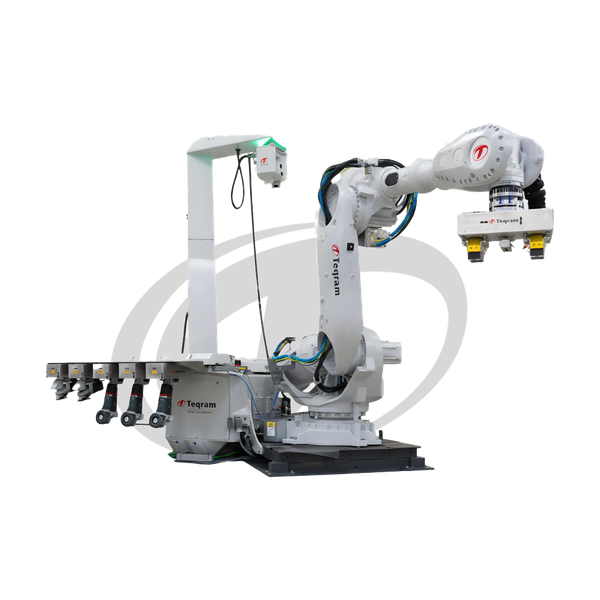

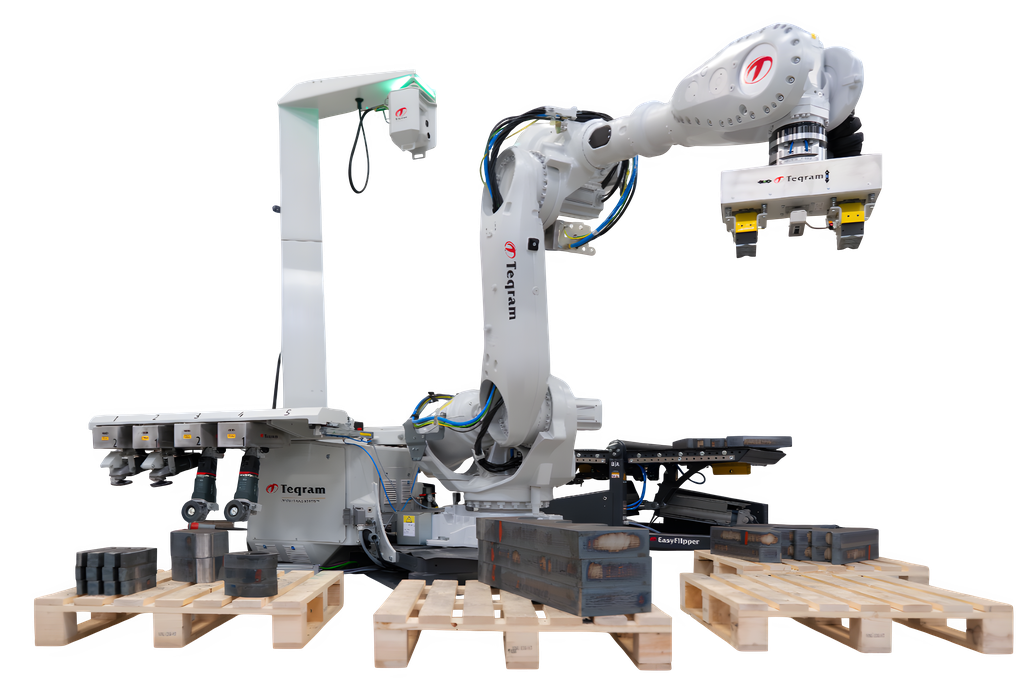

Discover Teqram’s Easy Robotic Solutions

Whether it’s EasyGrinder, EasyShotblast, or automated machine loading and unloading systems, all Teqram solutions are designed for your production needs. At the core: vision-guided control, modular grippers and tools, and an intuitive user interface — so you can get up and running fast.

EasyDebur automates your through-feed deburring machine and reduces the workload for your employees. Ideal for series production and demanding workpieces—including automatic flipping of parts, provided that one-sided deburring machines are used.

EasyMillDrill automates your machining processes. Workpieces weighing up to 600 kg [1,323 lbs] are placed into the machining centers and the program is started automatically. This includes flipping the parts, optional re-feeding, and external blowing-off of chips and coolant. This enables unmanned shifts and ensures perfect machine utilization.

With EasyGrinder, you achieve consistently precise grinding results—powerful, uniform, and reliable. Ideal for series production and demanding parts, EasyGrinder ensures perfect surface finishing and consistent material removal, all without manual effort.

EasyShotblaster automates your shot blasting and surface finishing processes while reducing the workload for your operators. Ideal for high-volume production and demanding workpieces, it reliably removes rust, scale, and surface contaminants — including gentle post-processing of sensitive surfaces.

EasyFlipper automates the flipping, feeding, and positioning of your workpieces, increasing both throughput and process reliability. Perfect for coating, assembly, and machining operations — with clean part handling, automatic flipping, and optional air blow-off.

Ready to automate your metal processing operations?

Get in touch with us to streamline your production with advanced AI-powered robotics — for efficient, future-proof automation.

Vision-Guided Robotics in Action

Our robotic solutions are deployed for robotic grinding, deburring, shot blasting, part leveling, and many other applications. With 3D vision-based part recognition, they operate fully autonomously — no programming required.

Explore our most popular robotic solutions:

Built on real-world experience. Designed for real-world production.

Teqram was founded on deep, hands-on experience in manual sheet metal processing. We know exactly where the challenges are:

- Physically demanding work

- Constantly changing parts

- High effort from changeovers and programming

These are exactly the problems we set out to solve.

With Teqram’s vision-guided robotics, we don’t just automate your processes — we simplify them.

No programming. No teaching.

Real-World Customer Success Stories

Automated Finishing with the EasyGrinder

UnionStahl, one of Europe’s largest steel service centers, uses the EasyGrinder to automate the post-processing of flame-cut parts. The solution eliminates physically demanding work, reduces labor and cycle time, and improves overall surface quality. Multiple finishing steps are combined into one fully automated workflow — with no manual programming required.

View Case (DE) →

Efficient Post-Processing at Doppelmayr Seilbahnen

Doppelmayr uses the EasyGrinder to fully automate deburring, edge rounding, and shot blasting of plasma-cut and oxy-fuel parts. The robot automatically detects part geometry, reduces labor requirements, and increases process consistency — while operators simply load raw parts.

View Case (DE) →

Automated Deburring at Liebherr-Werk Biberach

Liebherr uses a combined deburring and shot blasting solution from Teqram to automate the post-processing of heavy flame-cut parts. The system automatically recognizes each workpiece, eliminates physically demanding tasks, and improves both process reliability and surface quality — with no manual programming required.

View Case (DE) →Get all the insights in our free LinkedIn newsletter

Don’t miss the latest updates — subscribe to the Teqram newsletter right here.

Subscribe to the newsletterAt the Forefront of Robotics in Metal Processing

Robotics is transforming metal fabrication faster than ever. New technologies, practical solutions, and real productivity gains are emerging almost daily — while new challenges continue to appear. That’s why it’s more important than ever to stay ahead of current developments and learn from real customer projects and case studies.

Request Your Robotic Solution Now