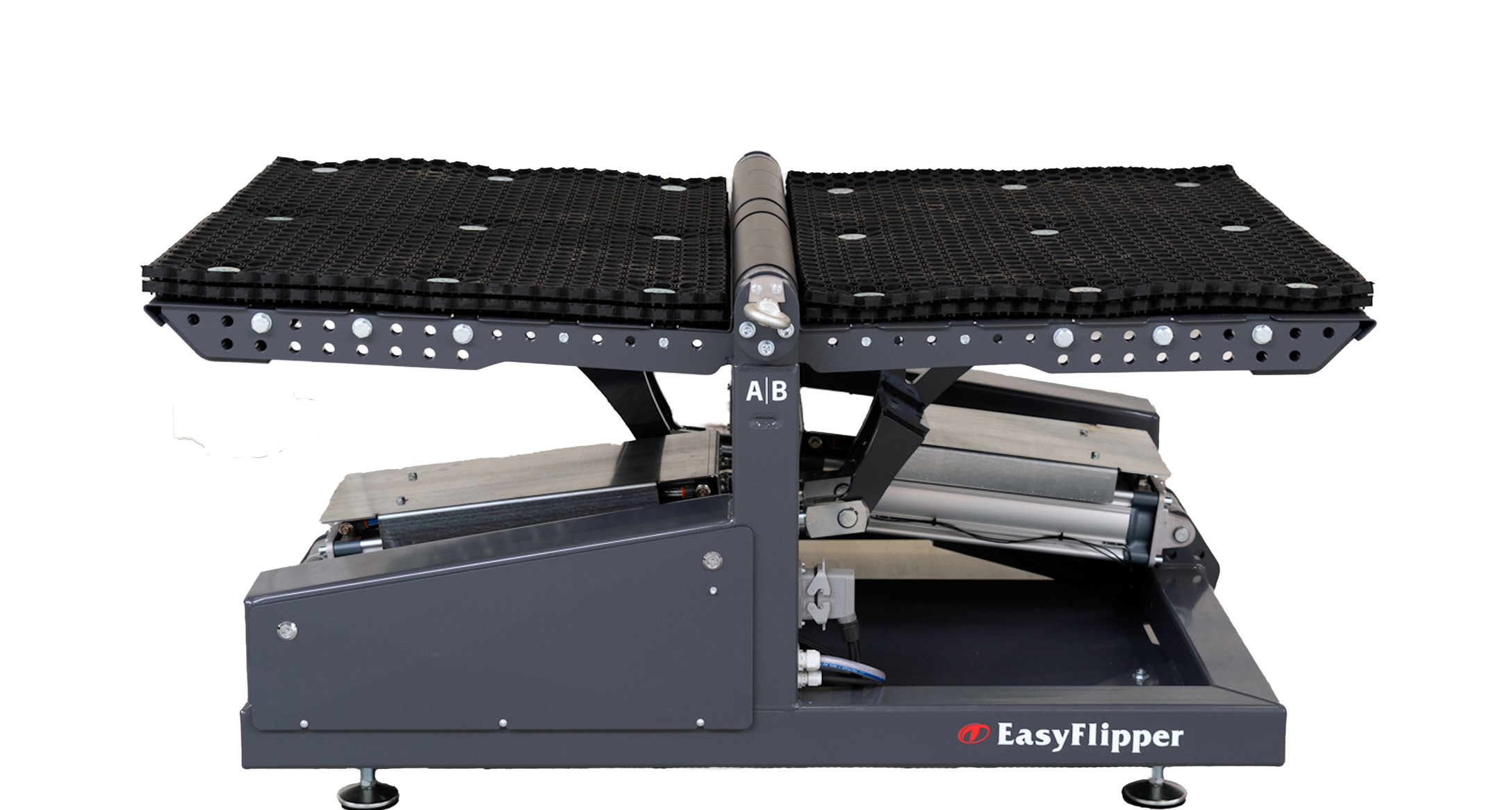

EasyFlipper

The EasyFlipper turns parts upside down within seconds. This solves a number of problems. In industrial operations, heavy (steel) parts are typically inverted using a crane with a plate-clamp or by means of a crowbar and sometimes even by fork-truck. This is time consuming, requires strenuous physical effort and is dangerous. In addition, there is a good chance that the part will be scratched and hence rejected. For inquiries: sales@teqram.com.

Watch this video for examples of the EasyFlipper in action

The EasyFlipper is often used as a working table for deslagging and grinding, and as a steel plate flipper or a sheet flipper. Its use as an industrial flipping device is popular for many applications where speed and safety are important...

Typical Applications

- Load rotation of heavy products

- Flipping oxy-fuel-cut or plasma-cut metal parts (e.g. to get the burrs facing upwards)

- Rotating steel or aluminum next to a CNC machining centre (to machine the opposite surface)

- Turning heavy laser-cut shapes next to a press-brake

- To view top & bottom sides of a metal part for quality inspection purposes

- Invert tear-drop plates

- Flipping heavy cut-shapes to fulfill customer packing requirements

Specifications

The main specifications of the standard EasyFlipper are:

- Table size: 1200 x 800mm

- Maximum part weight:

- Pneumatic EasyFlipper: 750kg / 1500lbs

- Hydraulic EasyFlipper: 2000kg / 4000lbs

- Connected EasyFlippers: a multiple of the individual EasyFlippers

- Cycle time:

- Pneumatic EasyFlipper: 5 to 10 seconds

- Hydraulic EasyFlipper: 35 to 45 seconds

- Flipper table is fitted with a rubber mat to prevent scratches

- Easy manual control and/or integration with our vision guided robots

- 230V / 110V + 6 bar air pressure

Dimensions of an EasyFlipper in mm [inch]

Unique features

For suitable applications, the EasyFlipper is a 'no-brainer'.

Speed

Inverts parts within seconds. The fastest solution to turn heavy parts safely.

Safety

Manually rotating heavy parts (by crane, crowbar or by hand) can cause serious physical injury. Put safety first by investing in the EasyFlipper.

ROI

Reduce manhours and increase physical distancing by mechanizing or automating the flipping of parts. The competitive pricing of the EasyFlipper ensures an attractive ROI.

Connect 2 or more EasyFlippers to rotate (very) long and heavy parts

![Dimensions mm [inch] of an EasyFlipper](https://media.tollenaar.io/images/image001_9_jRCifQP.width-1032.png)

![Dimensions mm [inch] of an EasyFlipper (height)](https://media.tollenaar.io/images/image002_3.width-1032.png)